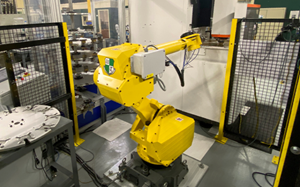

3 Technologies to Help Fill the Skills Gap

Moldmakers can address the labor challenge with robotic systems, simulation products and metal 3D printers.

#tips #3dprinting

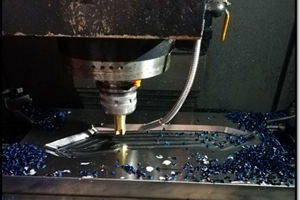

Indexable Milling Platform Advances Mold and Die Capabilities

The Dapra Vapor platform features elements in body design and TRI-X2 insert geometry for higher metal removal rates and extended tool life.

Tool Balancing Equipment Ensures Consistent Moldmaking Results

Zoller enables balanced toolholders, tool assemblies and grinding wheels using its »toolBalancer« series, providing high-quality surface finishes and extended surface life to spindles and cutting tools.

#workholding

High-Feed Mill Prolongs Cutting Tool Life

Keeping with its 100-year history in cutting tool design and manufacturing, M.A. Ford introduces the TuffCut HF high-feed mill.

High-Feed Milling Cutter Range Benefits Moldmaking Versatility

Horn USA offers a comprehensive DAH milling tool range, including the DAH37 high-feed cutter, DAH82 and DAH84 carbide grades and the DG range.

Shell Mill Supports Variety of Rough Milling Strategies

The Ceratizit MaxiMill 251 is optimal for pocketing, mold and die roughing, face milling, slotting and helical interpolation of holes.

Ball Lens Inserts are Engineered for Productivity, Surface Finish Gains

Millstar introduces the ABL series, providing a cutting tool solution that enables up to twice the stepover, reduces the need for multiple cutters and meets other moldmaking demands.

Mold and Die End Mills Target Hard Machining

More than 20 new options in Emuge-Franken’s hard-cut ball nose and torus end mills line offer up to 60% longer tool life and excellent surface finish when roughing, pre-finishing, finishing and high-speed cutting.

Space-Saving Five-Axis Provides Productive Mold Machining

The Grob G150 universal machining center and its spatial accuracy enhances its performance with complex, high-precision components.

#fiveaxis

Aluminum Machining Efficiency Improved With Milling Inserts

The TungAluMill line has been enhanced with 10 new XVCT-AM inserts, featuring an interface design that augments machining at high speed rates.

#aluminum