Hot Runner Tips, Apprenticeships & Waterline Maintenance, Oh My! MMT's June Top Hits

Take a look at MMT’s top hits from June based on Google Analytics.

VIDEO: How to Protect Your Hot Runner Systems

Chad Root Managing Partner for Fast Heat by Spark Industries reviews some molding machine integration concepts that protect hot runner systems, the molding machine, reduce scrap and help keep a log of events.

#ICYMI

Technology and Sourcing Guide 2023: Mold Maintenance, Repair & Surface Treatment

A proactive maintenance plan to properly treat a mold to keep it running will decrease repair costs. Proper treatment of the mold’s surface is key to quality, corrosion-resistance, wear and tool life.

VIDEO: Full, Automatic Waterline Maintenance

Tyler Boss and Scott Smith of DME Company review the key components of comprehensive waterline channel maintenance.

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

#education #auxiliaryequipment #basics

Hot Tip Sprue Cleaner Melts Obstructive Plastic

The hand-held tool from Globeius Inc. brings plugged hot runner sprues and nozzle tips back to life quickly and safely, sometimes without needing to remove the mold from the press.

VIDEO: Hot Runner Maintenance Tips

Scott Clark, Hot Runner Business Manager for Husky Technologies, breaks down maintenance practices for hot runner systems.

Mold Care, 3D Scanner Best Practices, the State of Maintenance & More Most-Viewed April Content

April held a little bit of everything for MoldMaking Technology. From mold care and maintenance to 3D scanner and printing best practices, take a look at what might have missed your radar.

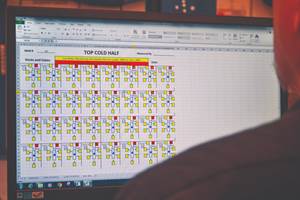

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

#industry40 #analysis #leadership

In-Mold Sensor Technology Assists With Sustainability Goals

SensXpert Digital Mold from Netzsch Process Intelligence is intended to help the plastics industry reach governmental and environmental sustainability goals.