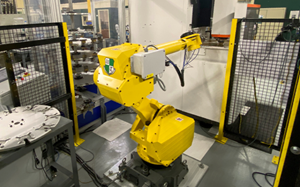

3 Technologies to Help Fill the Skills Gap

Moldmakers can address the labor challenge with robotic systems, simulation products and metal 3D printers.

#tips #3dprinting

AddUp, WBA Investigate Additive Manufacturing for Moldmaking Tooling Study

The additive manufacturing (AM) tooling study focused on six select companies, offering them the opportunity to test the introduction of AM and specifically implement the technical and economic advantages of AM technology for their injection molds.

#3dprinting

Mold Design Tricks, Additive Manufacturing Treats & More: MMT's Top-Viewed Articles in October

October held some tricks but mostly treats for MoldMaking Technology’s audience.

#3dprinting

The Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D-printed parts.

#3dprinting

Large-Scale 3D Printer, Print-on-Demand Services

PowerPrint is KraussMaffei’s latest launch in the additive manufacturing space that is maximizing design freedom and cost efficiency. It is available for purchase or serviced through the company.

#3dprinting

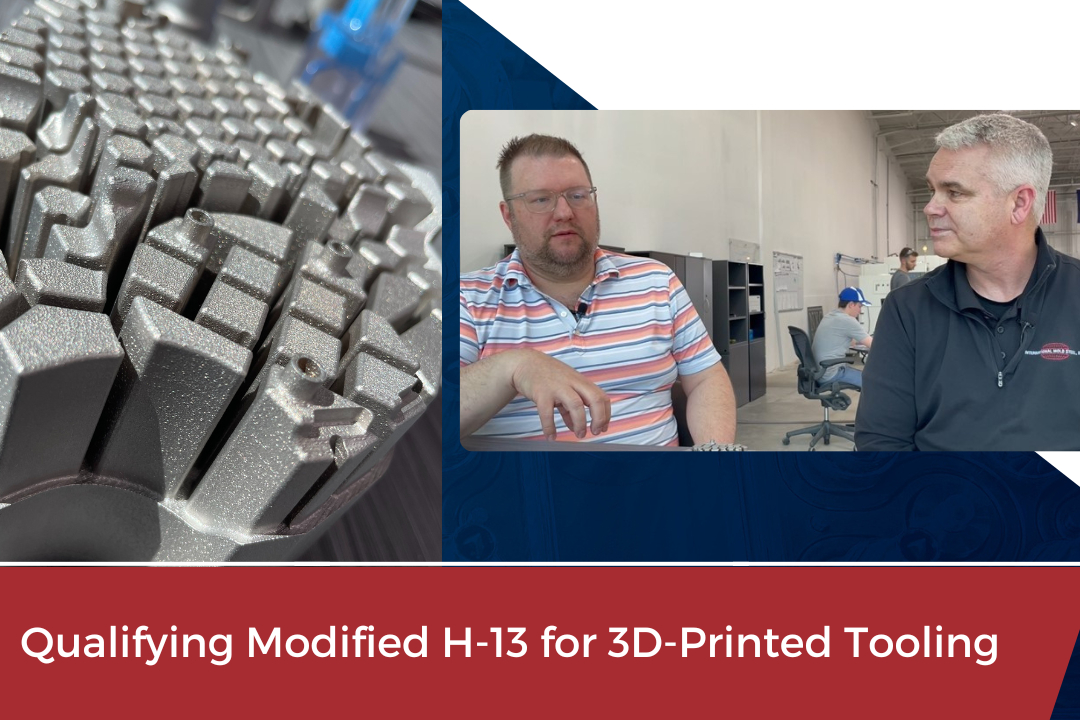

VIDEO: Qualifying Modified H-13 for 3D-Printed Tooling

Next Chapter Manufacturing and International Mold Steel discuss their partnership to qualify a modified H-13 for tooling applications.

#3dprinting #toolsteel

Robotic Metal 3D Printer Automates, Augments AM, Repair and Cladding

The ready-to-use Meltio Robot Cell plug-and-play solution integrates Meltio’s metal 3D printing technology with a robotic arm for safe, reliable and automated 3D printing.

#3dprinting

MMT Chats: Pushing Further 3D Printing Development for Tooling

Partnership yields improvements to how tooling components are made with a new level of precision, accuracy and surface finish right out of the printer. Hillary Thomas, Westminster Tool and Paul DiLaura, Mantle tackle these topics with MMT Editorial Director Christina Fuges. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

#3dprinting

MMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

#3dprinting

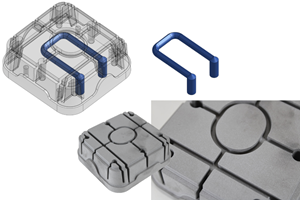

Mantle to Deliver Production Metal 3D Printers for Moldmakers, Molders

Demonstration of continued market momentum is seen by delivery of the P-200 printer to Westec Plastics and Westminster Tool’s success with a Mantle beta system. Mantle will be featuring these achievements at this week’s MoldMaking Conference.

#3dprinting

Mantle TrueShape Advances Medical Mold Manufacture

In a recent case study, Mantle’s 3D-printed inserts enabled a medical device manufacturer to reduce 12-week lead times for prototype mold production to 4 weeks and at one-third of the cost.

#medical #3dprinting

MMT Chats: Maintaining an Arsenal of Technology for Tight-Tolerance Work

Five-axis machining, hybrid AM, automation, rebranding and legacy. Lester Jones, Executive Vice President of Custom Mold & Design (CMD) tackles all these topics with MoldMaking Technology Editorial Director Christina Fuges. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

#fiveaxis #3dprinting

SLM 3D Printer Focuses on Complex Geometry Development

Newly launched DMG MORI Lasertec 30 SLM US 3D printer features adaptive beam control, noncontact recoating and a hybrid toolpath strategy for more dynamic additive capabilities.

#3dprinting

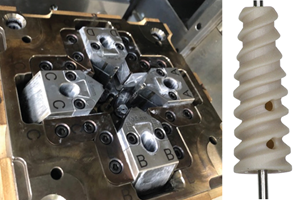

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

#casestudy #3dprinting

Optimized 3D Printer Targets Dental, Medical Applications

The new Trumpf TruPrint 1000 offers faster print speeds, higher quality parts and requires less floor space.

#3dprinting

CNC or 3D Printing: 5 Factors to Consider

Accuracy, time, cost, nimbleness and application considerations help to determine if a shop should use CNC machining or 3D printing.

#tips #3dprinting

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

#basics #FAQ #conformalcooling

3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

#conformalcooling #3dprinting

Qualified Tool Steel Enhances Thermal Transfer, Long Tool Life

Next Chapter Manufacturing has successfully qualified HTC-45 tool steel, an optimized version of H13, to support better thermal transfer and faster cycle times for molders and die-casters.

#3dprinting #toolsteel

Pellet Extrusion 3D Printing Raises Advantages in Thermoforming, Vacuum Forming Molds

3D Systems’ Atlas and Atlas-HS thermoplastic pellet extrusion 3D printers offer high-speed printing of molds with high-performance, high-temperature materials.

#3dprinting