Gundrill Tool Extends Hole-Making Productivity for Injection Molds

Minimized downtime, enhanced machine productivity and the ability to drill interruption and cross holds are some key features behind the Iscar Tri-Deep gundrill.

#drills

Cast Plate Aluminum Alloy is Suitable for Production Mold and Dies

Alimex Precision in Aluminum introduces its 7000 series ACP7 mold material, featuring high mechanical properties, material stability and good machinability.

#aluminum

Milling Cutter Handles High-Precision Moldmaking Requirements

Guhring offers industry the G-Mold µ line of cutters, which can withstand the challenge of machining mold materials with a high degree of flexibility and precision.

Indexable Inserts, Toolholders Perform Heavy-Duty, Wide Profile Grooving

The Tungaloy TungHeavyGroove’s enhanced insert clamping and reinforced toolholder designs achieve efficient grooving performance.

Cutter Designed for Roughing in Face, Profile Milling Operations

The Sandvik Coromant CoroMill MR80 now caters to steel milling applications, which require the security of a round cutting edge — for instance, when face and pocket milling mold bases.

#toolsteel

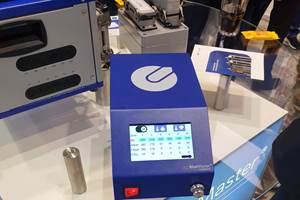

Temperature Control Unit, Hot Runner Heating Enhance Injection Molding Reliability

Günther debuts a slimmer, more efficient BlueFlow hot runner nozzle and the blueMaster check device to verify operations, now offered with an integrated display for users.

Robot Slicer Software Simplifies Wire-Laser Metal 3D Printing Technology

The Meltio Space toolpath generator employs a virtual model of real robot movement, empowering users to create intricate, customized and highly detailed 3D-printed metal parts.

Solid Ceramic End Mills Provide High Metal Removal Rates

Greenleaf Xsytin-360 end mills provide high material removal rates and result in increased productivity on a wide range of materials.

Solid Carbide Cutter Mills Aluminum

Roughing and finishing deep pockets and cavities are the primary feature strengths behind this Walter MC166 Advance cutting tool.

#aluminum

Extended mold plate range increases customer flexibility

More than 2,000 drilled and undrilled plate variants from Hasco enable the development and production of injection molding, pressing and die-cast tools.