Dry Ice Provides Optimum Range of Possibilities in Parts Cleaning Process

Cold Jet LLC showcases how they use dry ice (solid CO2) in their parts cleaning process.

When It Comes to Shop Safety, Think Beyond Pallets and Blocks

More often than not when touring a shop I see a unique approach to solving an everyday problem. This time it was a shop full of big, heavy molds that were not sitting on pallets or blocks across the the floor. Instead, they were sitting on top of small, plastic feet.

#ICYMI #safety #regulations

VIDEO: The Importance of Facility and Flow to Mold Repair and Engineering Changes

United Tool and Mold Owner Scott Phipps speaks with MoldMaking Technology Editorial Director Christina Fuges about its new 60,000-square-foot facility dedicated to large mold repair and engineering changes, which has improved the company's competitiveness and their future plans for growth and improvement.

How to Improve the Flow of Mold Repair and Engineering Changes

A new perspective on competition, training and workflow redefines this shop’s core competency in repair and engineering changes, and charges the team toward continuous improvement.

#basics #FAQ #education

Leadtime Leader Q&A: X-Cell Tool and Mold on Quality Assurance

The current Leadtime Leader shares an update on its continually advancing in-house quality processes and equipment.

#leadtimeleader

VIDEO: Elements of a New Age Repair Shop

Just as important as creating a solid maintenance plan for molds, is the shop in which the repair takes place. In this Toolroom Live Demo, Steve Johnson of MoldTrax presents an overview of a successful toolroom setup that includes a variety of essential bench and cleaning equipment on the market today.

#amerimold

Everything You Wanted to Know About Hot Runner Systems and How to Optimize Their Performance

MoldTrax Hot Runner Extravaganza brings a wealth of expertise and advice for making the most out of the hot runner design, function and performance.

#basics #FAQ

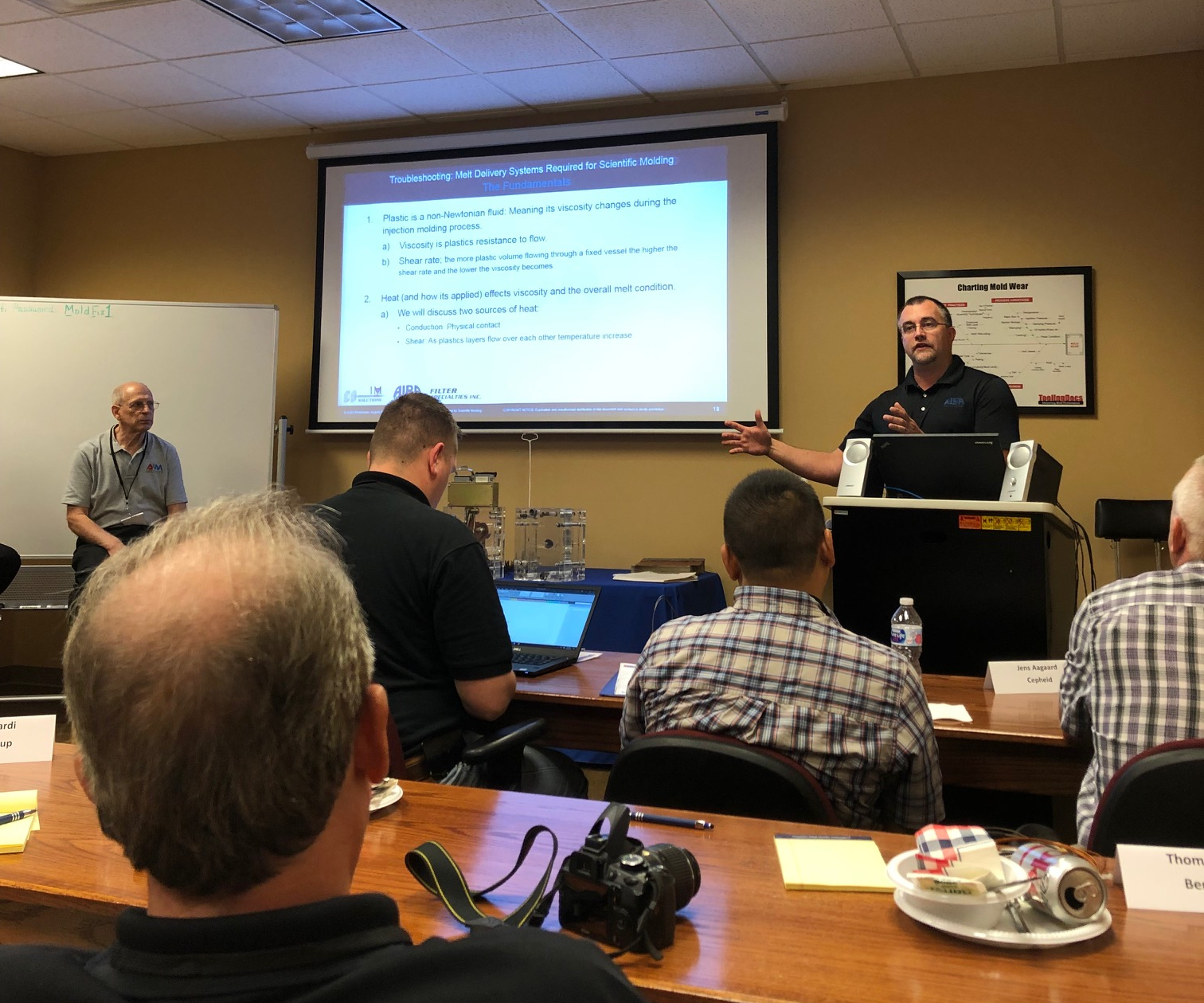

Getting Hot and Heavy during a Little Hot Runner Training

If a mold is the heart of a molding system, then the hot runner system is the heart of a hot runner mold, and I recently learned that there is a lot to know when it comes to designing and maintaining these systems to ensure optimal mold and part quality and performance.

#education

A 'Quality Without Compromise' Mindset and A Diverse Customer Base Gives Delta Mold More Peaks Than Valleys in Business

Quality-driven processes and focus on diversity in the markets served are key to Delta Mold’s continued success.

#profile

Femtosecond Lasers Improve Mold Texturing and Micromachining

Newer femtosecond laser machine option solves common working distance challenge for micromachining and mold texturing.