Hydraulic Locking Cylinders Come in Additional Standard Strokes

Off-the-shelf Kor-Lok “mini” model 70 and other side action systems by PFA come in more stocking options and next-day delivery to accelerate mold production.

Fast Wire EDM Targets 3D-Printed Mold Component Removal

EDM Network introduces the EDMMax 434W that enables customers to economically cut 3D-printed mold inserts from their build plates.

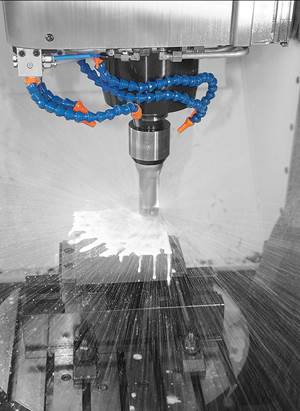

High-Efficiency Milling Excels in Specialized Parts Production

GF Machining Solutions Mikron Mill E 500 U offers moldmakers a sturdy, reliable five-axis machine with integrated automation opportunities.

#fiveaxis

Compact Robotic Palletizer Easily Automates Packaging Process

The Cube cell, complete with a KUKA KR50-R2500 robot, is targeted for small- and medium-sized businesses looking to automate the palletization of their end product.

#packaging

Large-Scale 3D Printer, Print-on-Demand Services

PowerPrint is KraussMaffei’s latest launch in the additive manufacturing space that is maximizing design freedom and cost efficiency. It is available for purchase or serviced through the company.

#3dprinting

3D-Printed Manifold Engineered to Eradicate Dead Spots Behind Valve Pins

Hasco Hot Runner introduces the Steamrunner Shadowfree hot runner system that aims to reduce material waste and elevate product quality in the injection molding process.

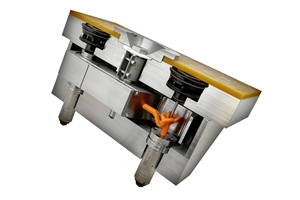

Hot Runner Nozzle is Enhanced With Interchangeable Needle Gate Chamber

Hasco Hot Runner introduces the replaceable needle valve prechamber Xgate to its Vario Shot nozzle series for precise needle guidance, resistance to aggressive plastics and as a tailored hot runner solution.

Automation System Loads up Expandability, Scalability and Precision for Moldmakers

The expandable, scalable, open architecture of the System 3R Transformer system by GF Machining Solutions permits integration of various technologies to optimize mold machining operations and meet any facility’s requirements.

Enhanced Jig Grinder Features Meet Manufacturing Flexibility Requirements

The Mitsui Seiki J350G offers mold and die-makers one of the largest available infeed stroke ranges to grind multiple features automatically without changing wheels, a smaller footprint and more advanced CNC controls.

Jig Grinder for Mold and Die Increases Rigidity for High Precision

The Hardinge Hauser 2000 combines grinding and hard milling features under one machine, featuring a dual-frame design, elimination of transverse forces and more to ensure highly accurate machining capabilities.