2012 Leadtime Leader Awards: M&M Tool and Mold: Niche Mfg Still Profitable

Surviving and thriving through an acquisition during a recession with an emphasis on lean principles and automation lands this former Leadtime Leader winner the MoldMaking Technology 2012 Leadtime Leader Award: Honorable Mention.

#marketing #leadtimeleader #casestudy

Growth of MMT Supporter and Leadtime Leader

It's always a good day when you hear of the success and growth of any reader of MoldMaking Technology magazine, but when it is a past Leadtime Leader Award winner and Editorial Advisory Board member, it is a little bit sweeter. Tech Molded Plastics, Inc.'s, a 2007 Leadtime Leader who has contributed much in the way of content to MoldMaking Technology magazine over the years, has expanded its facilities, which are now up and running. The company made major investments in facility up-grades, plasticizing technology, computerized monitoring of plastics processes, and advanced RJG training certification in plastics processing. Tech’s total footprint has almost doubled to over 92,000 sq ft.

#education #leadtimeleader

Leadtime Leader Takes on a Challenge

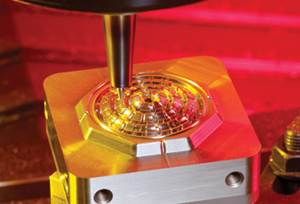

Can you really mold a pipette shaped part with a .015” wall x .370” long followed by a .008” wall x .080”? How about if the molding material is PEEK? How about 4 cavities? Can a Cpk of 1.33 be achieved on this wall section? These are the challenges and questions Mold Craft set out to prove the viability by partnering in flow simulation and press selection while Mold Craft designed and built a mold required for this difficult part.Although Mold Craft is typically known for their ability to design and build high cavitation production molds to produce parts that number in the hundreds of millions, Mold Craft has also received recognition for the ability to mold extremely tight tolerances on micro parts with intricate geometry that require high Cpk values. This challenge was just that, micro parts shaped like a funnel or pipette with extreme length to wall thickness ratio. To add to this complexity, the customer needed to use PEEK due to its high strength characteristics.Mold craft will be displaying their latest mold in the Sodick Plustech press at NPE in Orlando. Mold Craft (booth 1295) will have the attached photographed mold operating at Sodick Plustech booth 363.Read full story here.

#leadtimeleader

2011 Leadtime Leader Awards: Small Shop Honorable Mention

JM Mold South, Inc.: Constant Reinvention Results in Growth, Success.

#marketing #leadtimeleader #casestudy

2011 Leadtime Leader Awards: Large Shop Honorable Mention

MSI Mold Builders: Redefining Mold Manufacturing with Incremental Approval Approach.

#consumer #packaging #electronics

2011 Leadtime Leader Awards: Large Shop Winner

United Tool & Mold, Inc.: Charging Forward with Unique Mold Repair Niche.

#marketing #leadtimeleader

2011 Leadtime Leader Awards: Small Shop Winner

Mold-Tech, Inc.: Technology-Driven, Detail-Oriented Precision Injection Mold Provider.

#marketing #leadtimeleader

Triangle Tool: Product-to-Tool Service

This Large Shop Leadtime Leader Winner penetrates new markets with complete product-to-tool service while investing in technology.

#leadtimeleader

2010 Leadtime Leader Award Small Shop Winner Mold Craft, Inc.: Innovation with Automation

With an average leadtime of eight weeks, Mold Craft, Inc. (Willernie, MN)—this year’s Small Shop Leadtime Leader Award Winner—builds tight-tolerance, high-volume, multi-cavity and multi-mold projects that produce small, intricate, precision plastic parts.

#industry40 #leadership #leadtimeleader

Small Shop HM CS Tool Engineering: The Business Of Customer Service

Despite its location in Cedar Springs, MI—a state that has been hard hit by the economic downturn—CS Tool Engineering, Inc. has landed the 2010 Leadtime Leader Award Small Shop Honorable Mention by constantly investing in technology and offering its customers complete customer service with leadtimes between 10 and 12 weeks.

#consumer #automotive #marketing

Elite Mold & Engineering: Team Elite

Being both a moldmaker and a molder allows Elite Mold to be a one-stop team for its customers and the MoldMaking Technology 2009 Leadtime Leader Honorable Mention Award: Small Shop.

#consumer #electronics #medical

Byrne Tool & Die: A Culture of Change

This moldmaker takes employee training and development to a new level and relies on the latest in lean initiatives to get the job done quickly, earning them the MoldMaking Technology 2009 Leadtime Leader Award: Small Shop.

#leadership #education #leadtimeleader

Commercial Tool & Die: Innovation And Improvement Are Keys to Success

The company’s two mantras—customer service coupled with continuous improvement—have allowed this mold manufacturer to triumph during trying times while landing them the MoldMaking Technology 2009 Leadtime Leader Award: Large Shop for the second year in a row.

#leadership #marketing #leadtimeleader

StackTeck Systems Ltd.: Continuous Improvement Trims Leadtimes

This moldmaker’s maturing outlook on operations processing and scheduling, combined with continuous improvement initiatives, results in overall leadtime improvement of 15 percent and garners them the MoldMaking Technology 2008 Leadtime Leader Honorable Mention: Large Shop.

#leadership #casestudy #leadtimeleader

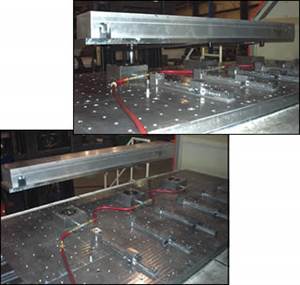

Extreme Tool and Engineering, Inc.: Embracing Change

This shop—never content to rest on its laurels—combines lean initiatives and the latest in technology to be a one-stop shop for its customers and win the MoldMaking Technology 2008 Leadtime Leader Award: Small Shop.

#consumer #packaging #electronics

Commercial Tool & Die: High Quality and Employee Innovation Drive Success

Unique, employee-developed programs tighten this moldmaker’s leadtimes—resulting in high quality tools delivered on time and the MoldMaking Technology 2008 Leadtime Leader Award: Large Shop.

#leadership #leadtimeleader #casestudy

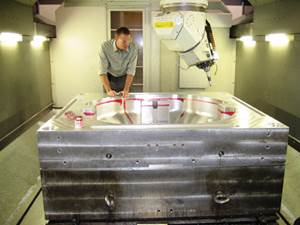

M&M Tool and Mold, Inc.: Automation Investment Pays Off Big

Heavily relying on lights-out manufacturing coupled with a niche market in complex mold manufacture, this moldmaker lands its fourth accolade as a Leadtime Leader—three times as a winner and this year’s Leadtime Leader: Small Shop Honorable Mention.

#industry40 #leadership #leadtimeleader

Synergetic M2M Group: A Global Presence

Overseas operations in more than 10 countries solidifies this moldmaker’s place in the world and earns them the MoldMaking Technology 2007 Leadtime Leader Honorable Mention: Large Shop.

#regulations #leadership #leadtimeleader

Tech Tool & Mold, Inc.: Strength and Flexibility

This moldmaker garners the 2007 Leadtime Leader Award: Small Shop by being flexible with its customers, going lean, competing globally and uniting with other moldmakers.

#leadtimeleader