Five-Axis Hard Milling Improves Electrode Accuracy

Fully automated, high-speed hard milling centers saved moldmaker time, money, handwork, allowed wider-range of EDM burns to be achieved.

#fiveaxis

2020 Sourcing & Technology Guide: EDM

MoldMaking Technology’s annual Technology Review and Sourcing Guide is a comprehensive guide for researching today’s technology, equipment, products and services with 11 sections, including EDM.

#supplychain

Graphite Machining Capabilities Enables Tighter Tolerances

Tri-Gemini has expanded its graphite machining capabilities for high complexity electrodes.

#amerimold

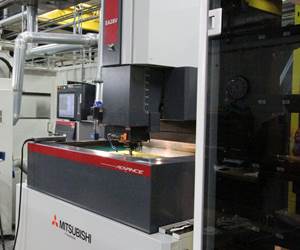

Investment in Advanced EDM Equipment Sets Shop Apart With Unique Wire EDM Capabilities

Extreme Wire EDM capitalizes on technology investment to carve out competitive advantages serving the moldmaking industry.

#workholding #leadership

Milling, Wire and Sinker EDM Equipment Optimizes Production

MC Machinery features several of the company’s innovative milling, wire and sinker EDM equipment.

#fiveaxis

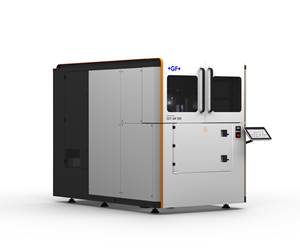

Spark Track Prevents Wire Breakage for Stable EDM Processes

GF Machining Solutions offers Spark Track technology for wire-cutting EDM.

EDM Speeds Up Additive Part Separation, Preserves Part Integrity

GF Machining Solutions announces the AgieCharmilles Cut AM 500, a horizontal wire EDM designed to complement metal additive manufacturing.

#3dprinting

Die-Sinking EDM Optimizes Micromachining Processes

GF Machining Solutions showcases the AgieCharmilles Form X 400 die-sinking EDM solution.

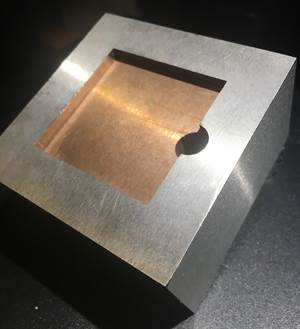

Design Capabilities and a Lean, Skilled Team Makes Do-Rite Die & Engineering a Valuable Source for Die Cast Dies

Do-Rite Die & Engineering’s skilled team knows how to achieve creating even the most complex details using EDM or a combination of electrodes and three-axis machining.

#profile

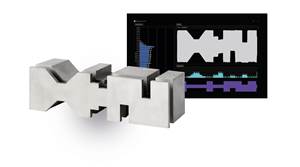

How to EDM Steel and Copper Alloy Simultaneously

A strategy for machining details when the part geometry falls across multiple workpiece materials.

#toolsteel #basics #FAQ