Control All 3D Scanning and Probing Measurement and Data

A metrology tool for feature-based part inspection.

#analysis

Integrating Electrode Production

How CAD/CAM can help make the design, machining and inspection of electrodes completely integrated.

#analysis

Working Your Way through the Welding Options

There are plenty of choices in welding technologies for mold repair. Here, a toolroom supervisor and his team share some at-the-bench knowledge of them to help you decide which one’s right for you.

#basics #FAQ

Raising the Bar on Better

A look at one project to move away from traditionally customized moldmaking toward a level of complete automation that raises the bar on accuracy, repeatability and control.

#fiveaxis #grinding #casestudy

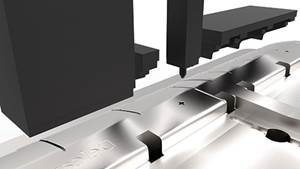

Mega-Cell: Moldmaking Automation

The Mega-Cell is a production system that ties together all available opportunities to automate and control the process.

#industry40 #workholding #fiveaxis

Keeping Molds Running

Technology advancements encourage moldmakers to think about surface treatment, mold maintenance and repair issues earlier in the mold build process to obtain better mold performance and life.

Inspecting Complex Product Profiles

Using metrology software and a portable CMM, mold manufacturers can efficiently handle exceedingly complex surface profile requirements.

#analysis

CT scanning: A Differentiating Factor

NyproMold finds its growth in differentiation—including using CT scanning to look through parts with an accuracy of 5 to 7 microns, obtaining information that can speed the mold manufacturing process.

#analysis #casestudy

Video: CT Scanning for Mold Inspection

Moldmaker NyproMold describes its experience using computed tomography (CT) scanning to validate precise injection molds.

#analysis

Micro Inspection at Matrix Tooling

Various inspection and measurement resources help a moldmaker produce tooling for tiny molded parts.

#analysis #casestudy