Mold Cleaner Uses EPA-Exempt VOC Compounds

Slide Products’ X-EMPT mold cleaner guarantees air quality regulation compliance for plastic processors.

#regulations

Ceramic Fiber Brushes Enables Fast, Automated Deburring and Surface Finishing

The automated Xebec Brush features woven ceramic fibers for consistent cutting action, high-speed finishing solutions.

Laser Processing System Integrates Automation For Complete Precision and Flexibility

ACSYS Lasertechnik’s Multishift system is fully automatic, including a robotic arm and integration with OCR, OPR and dynamic focus control for a very precise laser processing finish.

#industry40

Technology Roundup: Mold Repair, Surface Treatment, Misc.

MMT provides a brief glimpse at the mold repair, surface treatment and miscellaneous products/services highlighted in the February print and digital issue. Check them out now!

Rust Preventative Spray Formulated With Food-Approved Active Ingredients

NSF registered H-1, Slide Products’ White Rhino is ideal for molding operations requiring food-approved ingredients, including medical molding.

#medical

From CAM, Cutters and Cooling to Corrosion, Cleaning and Control

A review of the year’s top tips on technologies and strategies to improve moldmaking operations from design to first shot.

#tips #leadership

Dry Ice Is Essential for COVID-19 Vaccine Distribution

A leader in the manufacturing of dry ice production and blasting equipment and is currently helping industry and governments to safely distribute billions of COVID-19 vaccine doses around the world.

#medical #supplychain

Ultrasonic Polisher Enhanced For Highly Efficient Finishing

NSK America Corp.’s upgraded Ultrasonic Polisher Sheenus ZERO is ergonomically friendly, removes hard layers of EDM deposits and polishes difficult areas.

Gas-Heated Furnace Optimizes Mold Preheating

Grieve’s furnace heats up to 2000°F(~1093.3°C) and 7-inch-thick floor and wall installation enable consistent heating.

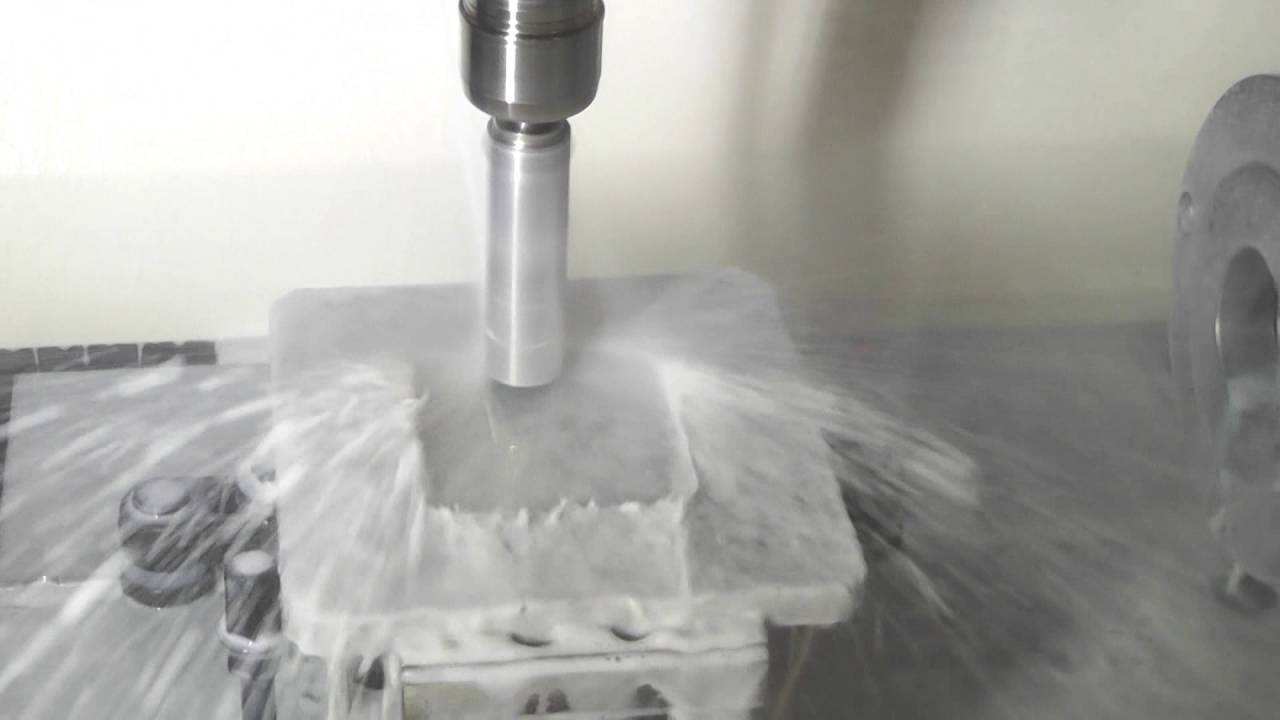

Components of a Complete Cleaning and Surface Treatment Program

Proper surface treatment of a mold optimizes the mold’s performance, limits downtime, improves performance and increases production efficiency.

#basics #FAQ