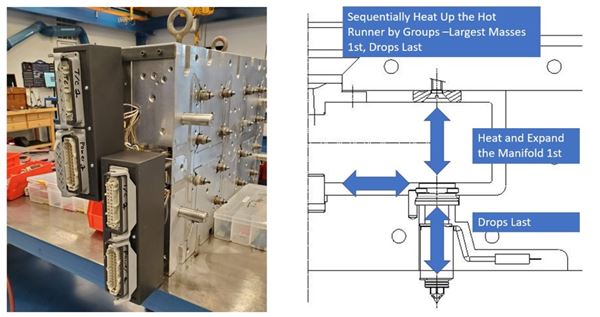

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Hot Runner Systems, Controllers, Auxiliary Injection Unit Exhibitions

Mold-Masters exhibits a wide variety of new and enhanced systems and technologies at K Show like the TempMaster manifold plastic leak detection, the PET-Series two-stage hot runner system and Fusion Series G3.

VIDEO: How Water Flow Monitoring Optimizes Mold Production

MoldMaking Technology Editorial Director Christina Fuges and Progressive Components' Rebecca Hamstra discuss why monitoring water flow in injection molds is important.

Tooling: ‘Eco-Friendly’ Rust Remover & Preventative

Water-based product from iD Additives removes rust and prevents its formation.

Database Helps Molders Limit Molding Out-of-Spec Parts

Mobile Specs offers a large, searchable database online and in app that provides molders with processing parameter set points for thousands of molding materials. Molders can use the site to reduce molding out-of-spec parts.

Injection Molding Technology Training Seminar Coming in August

Injection Molding Technology – Materials, Processing and Design Considerations is a seminar that will be held August 22-23 in Denver, Colorado, and is suitable for both experienced and inexperienced injection molding professionals.

Vacuum Units Offer Multiple Benefits

CUMSA has two new vacuum devices, the Double Action Vacuumjet (VB) and the Smart Vacuumjet (SV), at NPE2018.