Booster Unit Amplifies Microcellular Foaming

Trexel’s NC-Series Nitrogen Booster can reliably supply nitrogen supercritical fluid (SCF) to multiple satellite dosing units, creating a low-cost option to equip multiple molding machines with MuCell microcellular foaming.

#moldingequipment

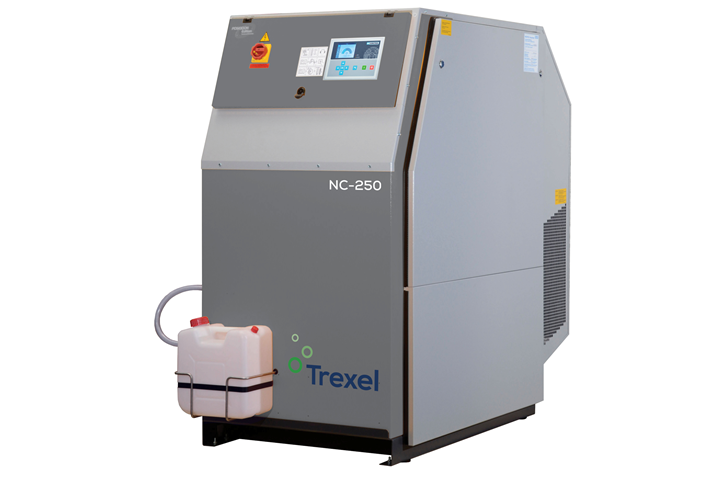

Photo Credit: Trexel Inc.

Trexel has introduced NC-Series Nitrogen Boosters to supply the nitrogen supercritical fluid (SCF) at the heart of its microcellular foaming technology to multiple Satellite Dosing Units, enabling what it says is a low-cost option to outfit multiple injection molding machines in the same plant with MuCell. The satellite dosing unit concept was first introduced at Fakuma 2018 to allow molders to run multiple MuCell enabled presses from a single gas booster unit. At that show, Trexel announced satellite dosing units available in the T- (general purpose) and P-Series (high-speed packaging) configurations.

The booster’s compact design eases placement on the shop floor, and since dosing and control occur upstream near each injection molding machine, this central booster can be placed as far away as the gas distribution lines allow. Trexel says the NC-Series boosters can be networked with a second booster to provide system redundancy.

There are two models available: the NC-250 (215 l/min) and the larger NC-500 (500 l/min), and Trexel says the nitrogen compressors are configured to be fully compatible with the company’s satellite dosing units, offering simple control, quiet operation and low maintenance. The units can run with bottled nitrogen, a compatible nitrogen generator or be fed nitrogen from a bulk liquid storage system.

The Trexel MuCell SCF satellite dosing and metering system is designed to reduce the cost of MuCell implementation. The system works by precisely dosing and injecting small amounts of SCF into the plasticizing unit of the injection molding machine to create a lower density, stress-free microcellular material structure in the molded plastic part.

The unit’s control system is built around a 10" graphical touch screen user interface. Set-up parameters only require the shot size and percentage of SCF content. From there, the system calculates everything else, optimizing SCF delivery during screw recovery.

RELATED CONTENT

-

Shared Engineering Expertise Overcomes Design and Delivery Challenges

Collaboration on part and mold design between a molder and mold builder were vital to overcoming design and production challenges for a unique automotive project.

-

8 Mold Design Decisions That Impact Automation

Making the right decisions during eight key mold design phases will avoid automation problems and save money on price, installation and operation.

-

Designing a Better Heat Exchanger - Part 1

In a three-part sub-series, we review considerations for mold water cooling systems.