Compact Stack Mold for Thin-Wall Packaging

Oerlikon HRSflow says the patent-pending design allows the use of smaller injection molding machines while still promising the high output a stack mold tool.

#packaging

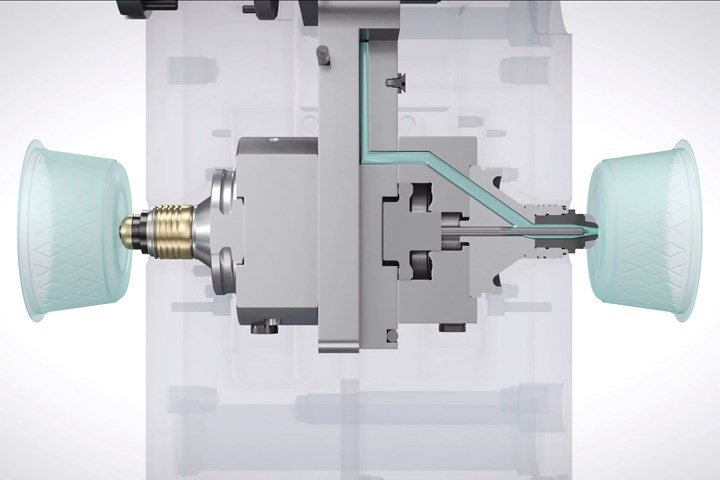

The center plate of Oerlikon HRSflow’s stack mold fits a maximum hot-half plate thickness of 220 mm. Photo Credit: Oerlikon HRSflow

Hot runner manufacturer Oerlikon HRSflow has designed a patent-pending compact stack mold for thin-wall packaging applications. Designed to withstand high filling pressures for thin wall packaging applications, the system, which will be available soon, can be run on lower tonnage injection molding machines and is equipped with the company’s Xd nozzle series.

The design fits a maximum hot half plate thickness of 220 mm with a minimum distance between the gates on either side of the plate of 260 mm. In a video released with the announcement, Oerlikon HRSflow showed a four-drop design molding two 210-mL single-serving cups in recycled PP with a weight of 6.3 g and a wall thickness of 0.3 mm on either side of the middle plate. What Oerlikon HRSflow calls a “mosaic” design on the cups’ walls was patented by moldmaker Collomb and imparts robustness to the container despite the thin walls.

RELATED CONTENT

-

In the Trenches: Tools of the Trade

Equipping yourself with the right tools for the job requires time, practice, ownership and maintenance.

-

Top Grade Molds Is All About Innovation and Collaboration

Top Grade Molds develops technology solutions with a heavy emphasis on R&D, recyclable material trends and collaboration.

-

Case Study, Software, Consumer Packaging: Enhance Your Quoting Process

The right scheduling solution allows for an effective quotation process.