Diamond-Coated End Mills for Machining Electrodes

Adding on to Crystallume’s Standard Premium and Lightning coatings is Stealth, the company’s thinnest diamond coating for highly detailed moldmaking work.

Crystallume, known for its chemical vapor deposition (CVD) diamond technology, features its three diamond-coated tool lines — Standard Premium, Lightning and Stealth — for machining the thinnest details in graphite electrodes.

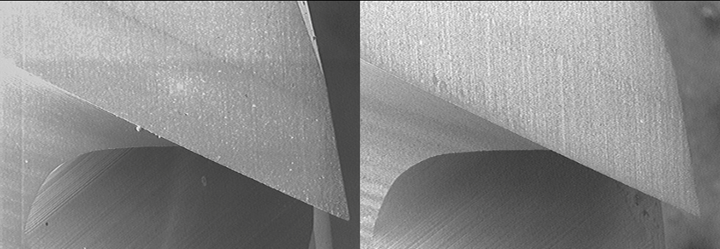

The company’s newest and thinnest diamond coating, Stealth, is only 2-3 µm thick, ensuring that tools with the coating have the sharpest solid diamond cutting edge available, according to the company. Depicted in the images above via scanning electron microscope is a cutting tool with the Stealth coating (left) and one without (right).

Four-flute Stealth end mill series are available, with a cutting diameter of 1/32 to ¼ and overall length of 1.5-4".

RELATED CONTENT

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

7 Key Advantages of Hot Runner Systems

While both hot runner and cold runner systems have their benefits, for design flexibility as well as reduced cycle times and costs, hot runner systems will probably be the better choice.

-

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.