Hybrid Multitasking Five-Axis Brings Subtractive, Additive Processes to Moldmakers

Mazak’s VC-500A/5X vertical machining center delivers hybrid multitasking and hot wire deposition to meet machining and additive needs.

#fiveaxis

Space-Saving Five-Axis Provides Productive Mold Machining

The Grob G150 universal machining center and its spatial accuracy enhances its performance with complex, high-precision components.

#fiveaxis

Five-Axis VMCs Attend to Versatile Machining Task Needs

Mold shops can choose from YCM Technology’s CF/CX or RF/RX Series of machines whether for simple or more demanding machining operations.

#fiveaxis

High-Efficiency Milling Excels in Specialized Parts Production

GF Machining Solutions Mikron Mill E 500 U offers moldmakers a sturdy, reliable five-axis machine with integrated automation opportunities.

#fiveaxis

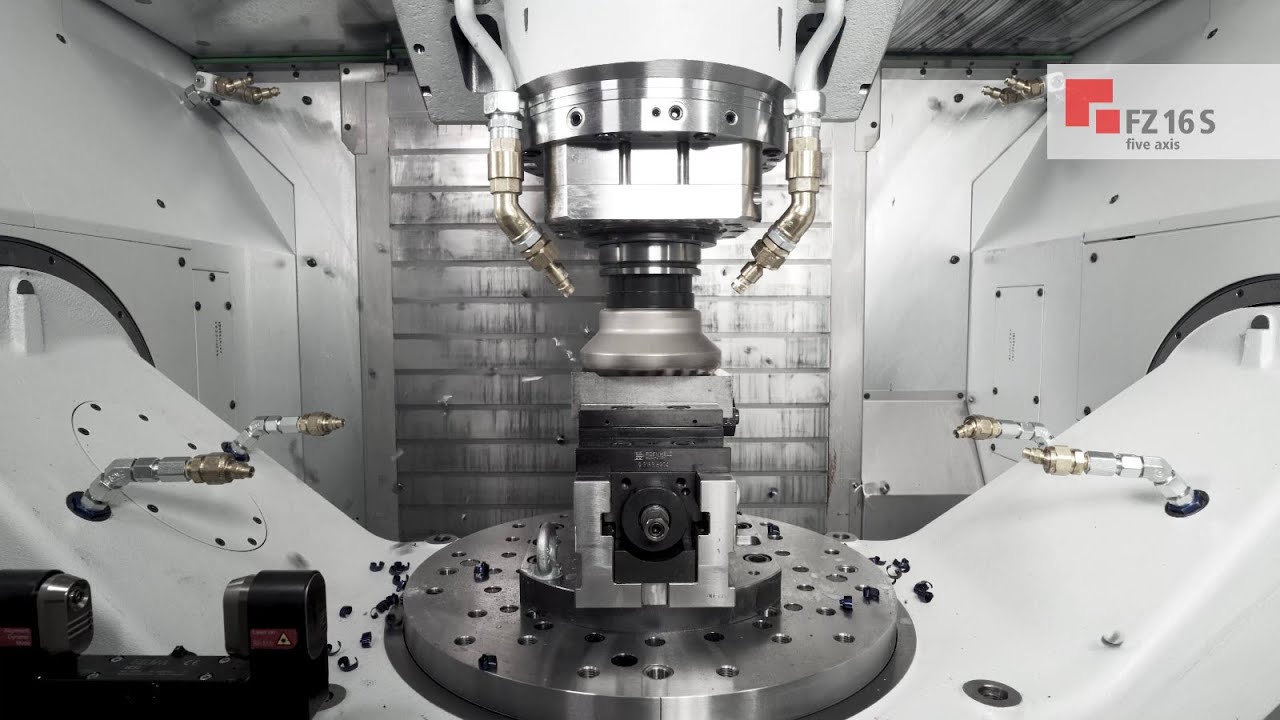

Machining Center Provides Robust, Dynamic Milling Qualities

Roughing and finishing deep mold and die cavities is optimized using Chiron’s FZ 16 S five-axis machining center equipped with an HSK-A 100 interface, enabling reduced chatter, dynamic machining and the ability to tackle difficult materials.

#fiveaxis

Five-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

#fiveaxis #casestudy

Five-Axis Machine Expands Advantages for Moldmaking

Optimized tool path and cutting angle control, access to hard-to-reach surfaces and overall efficiency and precision make Expand Machinery’s Gen Mill 5X-24 machining center optimal for the mold and die industry.

#fiveaxis

Design Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

#profile #moldingequipment #fiveaxis

High-Precision VMC With Unrestricted Five-Axis Machining

The Mikron Mill S 200 U is GF Machining’s vertical high-speed machining center well suited for tool and moldmaking and exact part production.

#fiveaxis

MMT Chats: Maintaining an Arsenal of Technology for Tight-Tolerance Work

Five-axis machining, hybrid AM, automation, rebranding and legacy. Lester Jones, Executive Vice President of Custom Mold & Design (CMD) tackles all these topics with MoldMaking Technology Editorial Director Christina Fuges. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

#fiveaxis #3dprinting

Five-Axis Machine With Pallet Changer, 16k-Spindle, Versatile Control Makes More Accurate Molds Faster

The move from three- to five-axis machining with automation reduced setup times and improved surface finishes for this small but mighty Amish mold builder.

#casestudy #fiveaxis

New Michigan Technical Center for YCM Alliance

YCM Alliance held a grand opening of its new Technical Center in Sterling Heights, Michigan, last week, which is the first in a series of centers designed to showcase and demo machining solutions for die and mold machining, ultra-high-speed machining and general parts machining.

#fiveaxis #highspeedmachining

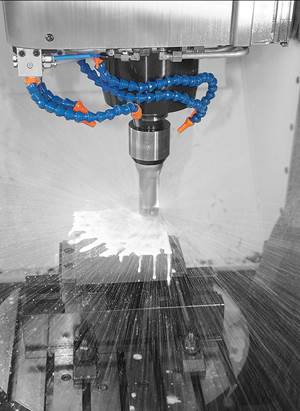

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

#basics #FAQ #fiveaxis

Stability, High Speed, Flexibility of Five-Axis Portal Milling Machine Reduces Rework for Mold Builder

The thermo-symmetrical construction of a five-axis portal milling machine with a center-guided Z-axis enables higher accuracy, reducing rework. Also, the symmetrical design and the guide arrangement increase stability and save weight, making the machine more dynamic, productive and energy-efficient.

#fiveaxis

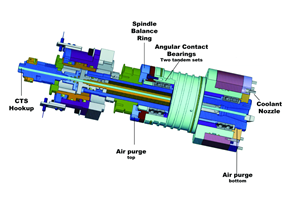

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

#basics #FAQ #fiveaxis

Cross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

#education #profile #fiveaxis

True Five-Axis Machine Yields More Throughput, Greater Productivity

CDM Tool & Mfg. Co. LLC increased shop capacity thanks to a versatile high-speed/high-accuracy five-axis Fooke mill capable of cutting very large workpieces quickly and accurately with fewer setups.

#fiveaxis #casestudy

Five-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

#fiveaxis #casestudy #industry40

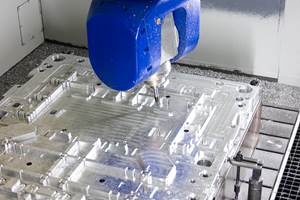

Developments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

#fiveaxis