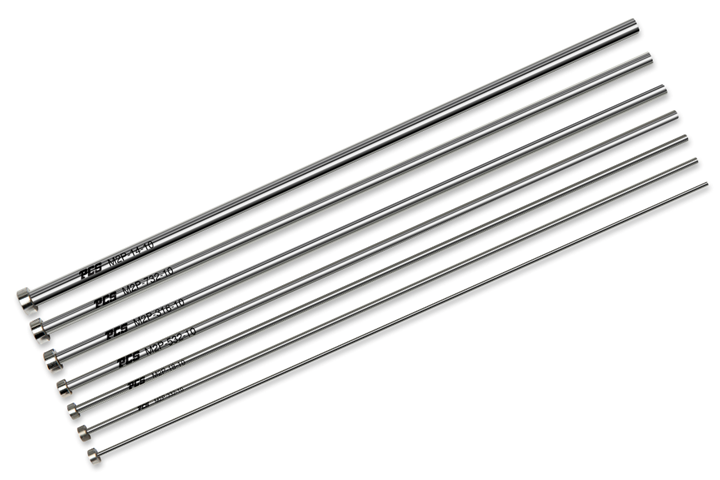

High-Speed Steel Ejector Pins for Plastic Injection Molds

Latest addition to PCS’ line of ejector pins features high carbon content for higher wear resistance in high-speed steel pins.

PCS Company introduces M-2 ejector pins, an enhancement to its already extensive line of high-quality, precision ejector pin products for plastic injection molds.

M-2 ejector pins are made of high-speed steel, which gives them higher wear resistance and better machineability than other currently available pins, according to PCS. Pin diameters range from 1/32" through 1/4" with lengths of 6" and 10". The diameters are precisely ground to provide dimensional stability and high surface finish quality .

“The M-2 ejector pins were added for customers who, increasingly, are requiring the specification of M-2 high-speed steel for their particular molding applications and tool designs,” Paul Hauser, product manager, says.

M-2 ejector pins are through hardened to 60-63 RC, with a diameter tolerance of 0.0003". Additional features include eliminating chipping from form work and their ability to be used either as an ejector pin or core pin

RELATED CONTENT

-

Enlarged Ejector Range to Cover Moldmaking Applications

Hasco says the approximately 600 additional new versions gives its ejector portfolio maximum demolding flexibility.

-

Ejector Portfolio Expansion Takes on Demolding Challenges

A number of ejector pins, sleeves and flat injectors, as well as an online ejector configurator have been added by Hasco for the functional demolding of molded parts.

-

Ejector Pins With Ventilation Surfaces Improve Mold Performance

Hasco America’s newest ejector pins feature extra-long ventilation surfaces so that air can more easily escape cavities within the mold.