HTS International Optimizes Conformal Cooling with iTherm Technology

Appears in Print as: 'Conformal Cooling Technology Cools Challenging Inserts and Cores'

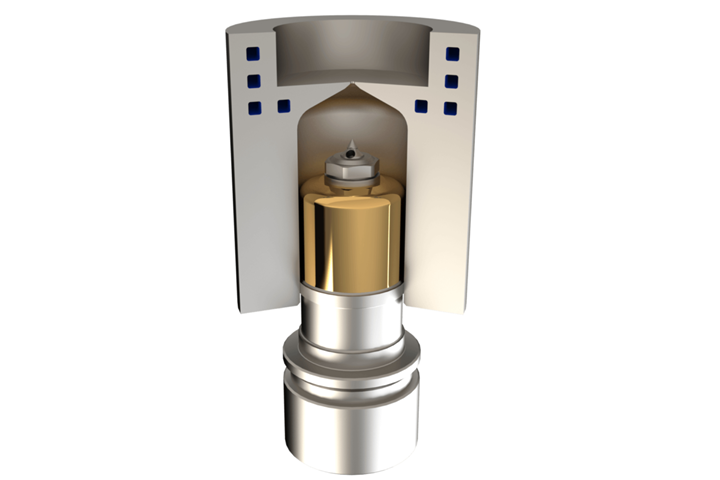

Amerimold 2021 exhibitor HTS introduces iTherm for injection molds, which can be integrated through any toolshop with various options for manufacture.

#conformalcooling #amerimold

Edited by Grace Nehls

Photo Credit: HTS

HTS iTherm, which can be integrated through any toolshop, with various options for manufacture, offers conformal cooling for injection molds, improving the ability to cool challenging inserts and cores, and often reducing cycle time or improving part quality. Material options include H13, 420SS and other standard tool steels.

Example components will be on display at Amerimold this September, where attendees can consult with expert engineering staff about design solutions for improving their tooling.

Exhibitor: HTS International Corp.

Booth M-929

RELATED CONTENT

-

Mold Material: Electroformed Composite Molds

Could a mold with electroformed composite inserts save you money?

-

Reduce the Time and Costs of Jig and Fixture Manufacture

When it comes to the manufacture of jigs, fixtures and assembly tools, time-to-market for new products can be reduced, overall costs can be saved and the quality of the resulting components/production can increase with the use of additive fabrication—laser sintering and fused deposition modeling.

-

Growing AM's Presence in Moldmaking

Advanced Michigan mold manufacturer advocates for additive manufacturing in moldmaking through collaboration and education.