IMS Software, ModuleWorks, Mastercam Collaborate on G-Code Simulation

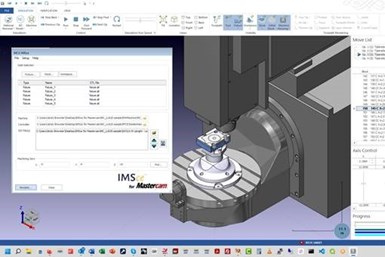

IMS Software, ModuleWorks and Mastercam’s IMSce combines IMS G-code emulation with the ModuleWorks simulation and postprocessing technology to provide a G-code parsing solution that connects directly to Mastercam.

Photo Credit: IMS Software, ModuleWorks, Mastercam

IMS Software, ModuleWorks and Mastercam have collaborated on the development of IMSce for Mastercam. The software solution extends the Mastercam machine simulation with G-code parsing and verification for diverse machine tools and controllers.

IMSce for Mastercam combines IMS G-code emulation with the ModuleWorks simulation and postprocessing technology to provide a G-code parsing solution that connects directly to Mastercam. The solution enables Mastercam users to simulate and verify G-code, including controller variables, subprograms, expressions and canned cycles for a range of machine tools before the workpiece is mounted on the machine.

“There is big demand for G-code simulation and it’s great to see how the technologies of different companies are being combined to create value-adding solutions for the industry,” Julia Meyer-Hendricks, head of business development – digital manufacturing at ModuleWorks, says.

According to Dan Wrenn, president and co-founder at IMS Software, integrated G-code simulation and verification is a major step forward in complex multi-axis machining, improving code quality and dramatically reducing overall programming time versus traditional standalone solutions.

“We are excited to work together with these industry leaders to offer G-code simulation running inside Mastercam for a wide range of machine tools and controls,” Stas Mylek, partnership program manager at Mastercam, says. “As a result, Mastercam users can leverage digital twin technology to simulate and validate their CAM programs, particularly for multi-axis applications, prior to running on their CNC machines.”

RELATED CONTENT

-

Quick Math for Cylinder Calculations

Simple cylinder calculations provide good first look comparisons for proper sizing when moldmakers are considering the most suitable side-action option early in the mold design.

-

Choosing CAD Software For 3D Mold Design

The world of CAD offers many alternatives to shops that want to use the latest 3-D technology for their mold design. This article looks at the benefits of the various approaches and offers some tips on choosing the most appropriate one.

-

Exploring ISO 9000 -Part 14 Corrective and Preventive Action

A Series of International Standards for Quality Management and Quality Assurance