Inline Water Filters Keep Mold Cooling Channels Clean

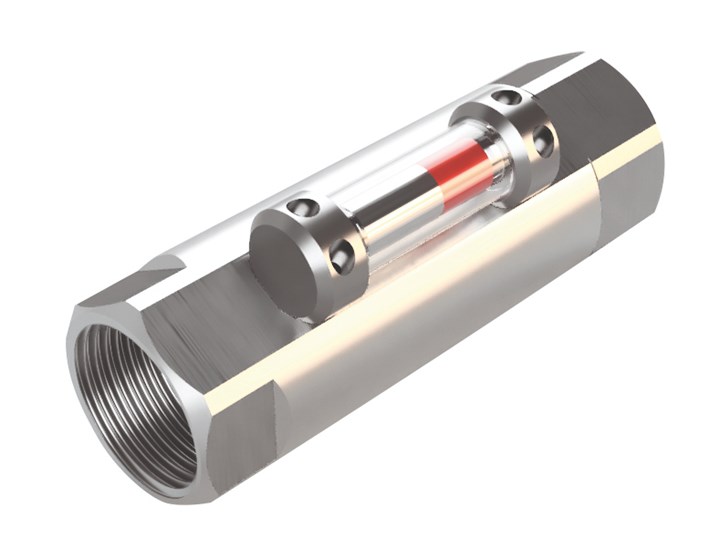

Mouldpro filters, distributed in North America by Globeius Inc., are adept at dirt particles, rust or water scale deposits.

Photo Credit: Mouldpro ApS, Globeius Inc.

A new line of inline water filters from Mouldpro ApS, and distributed in North America by Globeius Inc., help keep cooling channels clean in injection molds.

Mouldpro offers a variety of inline water filter products, including a filter that has a built-in maintenance indicator. The indicator shows when the filter is clean, and moves down accordingly when it’s dirty and needs cleaning or replacement. This feature in particular is adept at saving operators from clogged cooling lines, which lead to costly maintenance and downtime.

“These products remove dirt particles, rust or water scale deposits from a mold’s cooling channels,” Graeme Sands, general manager of Globeius, notes. “They are low-cost products that can save some very potentially high costs by preventing downtime.”

Made in Europe, the Mouldpro filters are easy to clean and maintain and consist of two housing parts and a filter. The filter inserts can be cleaned in an ultrasonic bath, or simply replaced; Globeius stocks the replacement cartridges.

The new maintenance indicator option is available on standard and stainless steel filters. The latter are ideal for conformal cooling tooling channels. They are suitable for use with water- or oil-based coolants with a flow volume up to 80 l/min, within a temperature range of -10 to 260°C.

RELATED CONTENT

-

LSR Cold Deck Design Facilitates Repeatable, Short Production Cycle

Mastip’s LSR solution fits mold plates, manifold and nozzles with cooling channels to ensure the curing cycle only once it enters the heated cavity plates.

-

CAD/CAM Software Generates Unique Additive Tool Paths for Mold Cooling Channels

The Open Mind hyperMILL Additive Manufacturing solution offers a variety of additive/hybrid functionalities, including toolpath strategies for designing intricate conformal cooling in a multi-axis machining setup.

-

Die-Cast Mold Conformal Cooling Achieved Through Hybrid Multi-Material 3D Printer

The DMG MORI Lasertec 65 DED hybrid combines 3D printing with milling to manufacture cooling channels in a single setup.

.jpg;maxWidth=970;quality=90)