Editorial, News, and Products

What You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

PTXPO Preview 2023: Mold Material/Mold Base Needs

At PTXPO 2023, the Moldmaking Pavilion returns, housing exhibitors ready to meet attendees' mold material and mold base challenges head on.

Three Considerations for Mold Steel Selection

Although a big challenge is selecting the right steel for the right job, steel selection has never been better in regards to quality, price and delivery speed. Here is a simple checklist when selecting your next mold steel.

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

MMT Chats: Advanced Manufacturing Program--Passion, Potential & Unlimited Career Possibilities

MoldMaking Technology Editorial Director Christina Fuges chats with the Advanced Manufacturing Design Technology Team at Central Community College in Hastings, Nebraska, about the new facility expansion and their 100 years of instructor experience that helps to mentor students from drafting, manual machines and CNC to part, mold and die design and advanced machining.This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

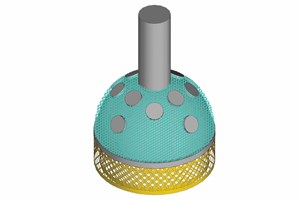

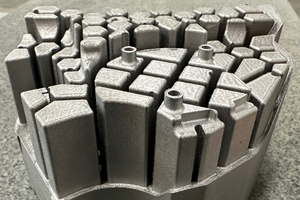

Evaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

VIDEO: What Does Integrated Predictive Modeling Mean to Moldmaking

Although conformal cooling is not a new concept, new technologies have made it a very hot topic, including predictive engineering models and 3D printing. Learn about a new conformal cooling process and algorithm and what it reveals about hot spots and conformal cooling design.

“Molds Make a Difference” at the Plastics Technology Expo

That was the sentiment of every person who came up to the MoldMaking Technology booth during last week’s Plastics Technology Expo to grab their giveaway “Molds Make” t-shirt after working the aisles seeking technology and process solutions and making new business connections.

Amerimold 2021 Post-Show Flashback: Engineer

More moldmaker exhibitor highlights from Amerimold 2021, from a P20-modified mold steel grade and free-machining stainless steel mold base material, to an automated knowledge-based mold design solution.

Videos Answer Hot-Topic Moldmaking Questions

Eight questions MoldMaking Technology asks industry experts about CNC controls, the changing training landscape, the human resources and marketing keys to workforce development, predictive engineering, data, visual search, OEE monitoring and additive venting.

Exploring AM Powders for Tooling

More options in AM tooling materials exist today that provide properties for crack resistance, thermal conductivity and heat treatment.

Expanded Service Capabilities Include Tool Steel Laser Engraving

International Mold Steel’s laser engraving service is offered in-house at a reasonable price.

Uniform Steel Hardness Offers Even Machinability

International Mold Steel, Inc. offers uniform hardness for even machinability and clean welds in molds and dies.

2019 Technology Review: Mold Materials

MoldMaking Technology’s 2019 Technology Review and Sourcing Guide offers some of the latest highlighted products and services from supplier companies from a variety of categories, including mold materials.

Steel Resists Wear from Abrasive Resins, Extends Tool Life

DC53 is a fully hardenable mold steel from International Mold Steel that withstands wear from abrasive resins.

Mold Steel Composition Streamlines Moldmaking Process

A mold material’s performance characteristics, like uniform hardness and dimensional stability, enabled Dramco Tool Co. Inc. to build a compression mold faster and more economically.

2018 Technology Review and Sourcing Guide: Mold Materials

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including mold materials.

Welding Pre-hardened 40 Rockwell Material

Key tips help ensure safe shop welding practices when using pre-hardened 40 Rockwell material.

Pre-Hardened Steels Eliminate the Need for Secondary Machining

International Mold Steel says its steels save moldmakers time by eliminating the need for heat treat.

Pre-hardened Steels Eliminate the Need for Heat Treat

International Mold Steel says its steels save moldmakers time by eliminating the need for heat treat.

Performance and Price Drive Developments in Mold Materials

Mold material suppliers are working to develop new, improved mold-material grades that will deliver on customers’ need for machinability, toughness, thermal conductivity and price.

Top-Viewed Articles on MMT

Click through the slideshow to see which topics have been of particular interest to the MMT community over the years.

Fun Friday: The Moldmaking Community Shows Patriotism, Heart and More

On September 15, 2017 our team at Alliance Specialties and Laser Sales partnered with our friends Tim and Kim Bartz from iWarriors and Mold Craft to host the inaugural Alliance iWarriors Charity Golf Outing.

Moldmaking Hits Nebraska

Looking for an opportunity to see what’s new in products and technologies for mold building and molding? Then join MMT on October 3rd in Grand Island, Nebraska.

Amerimold 2017: Multitudes of Metalworking Materials and Machines

Amerimold proved once again that it is THE event for moldmaking.

SLIDESHOW: Technology Showcase, MMT Surprise

This week's slideshow is an MMT 'Surprise' Showcase, editor’s picks for the week.

Getting Schooled in Mold Material

I met Roland Krevitt shortly after we launched MoldMaking Technology magazine back in 1998 and he had a wealth of experience and stories to share back then. He is still sharing them today. They are mostly about his experience with mold materials, which is always quite the hot topic with MMT's readers, so I thought I'd let him share some of his experiences here with you.

The Potential of Enhanced Venting Materials

Stop fighting venting problems with mold retrofits and prevent them by designing the original mold with an enhanced venting steel.

Get Schooled on Mold Material Selection

The evolution of pre-hardened mold steels was presented during the "Global Advances in Pre-hardened Mold Steels" webinar by International Mold Steel last month, and audience members walked away learning these five facts about mold steels.

WEBINAR:The Evolution of Pre-Hardened Mold Steels

Mold material selection has been a hot topic this year. MMT has hosted webinars, published articles and even secured speakers for the upcoming Amerimold Expo on the subject. For a look at global advances in pre-hardened mold steels tune into a webinar on Tuesday, June 9 at 2:00PM EST.

Becoming a Master of Mold Material

The right mold material for the right job can have a tremendous impact on your manufacturing process, and sometimes that means trying something new.

Material Matters

Hardness, machinability and strength are the bottom line as materials manufacturers and suppliers continue to reduce moldmakers’ leadtimes without sacrificing quality or cost.

Selective Materials Strategy Is A Potent Tool for Moldmakers

Reducing mold build costs with different steels and coatings may give North American shops more business from electronics OEMs.

It's a Material World

Strength, hardness and machinability are the common buzzwords that come into play when examining the new materials on the market.

Steel Selection-Closing the Gap with Offshore Tooling

To be competitive, domestic mold builders need to consider that steel selection-although the smallest portion of the overall mold manufacturing cost-can be a vital component in competing against cheap offshore tooling.

Hanging Tough

Fallout from the recent imposition of tariffs on steel imports may raise domestic steel prices and further drive business out of the country.

Cost Cutting

Knowing where to cut costs in this economy might determine if your company sinks or swims.

Pre-hardened Tool Steel Saves Time and Money

Using NAK 55 standard mold bases allows moldmakers to focus on crucial core and cavity work.