Mantle Unveils New Medical Mold Applications Achieved Through Metal 3D Printing

New applications from Nicolet Plastics and Westec Plastics become a testament to the strong adoption of Mantle’s metal 3D printing technology.

#medical

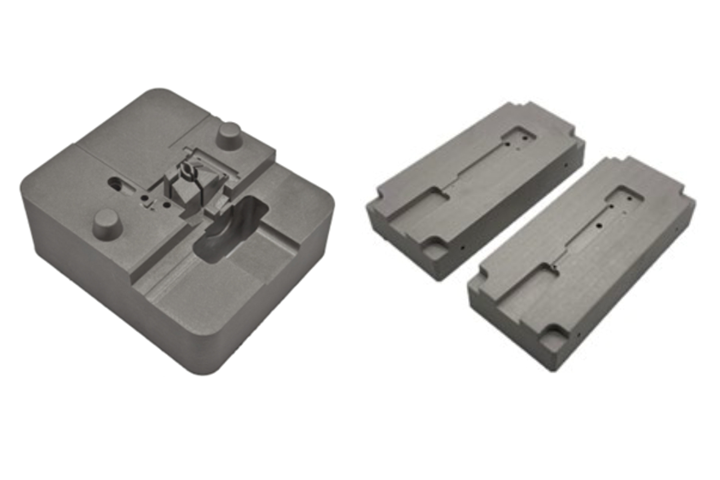

Nicolet Plastic’s printed H13 inserts (left) and Westec Plastic’s printed H13 inserts (right). Photo Credit: Mantle

Mantle Inc., a company developing metal 3D printing technology for toolmaking, has announced two new examples of customers successfully adopting Mantle technology to automate their toolmaking processes. Nicolet Plastics and Westec Plastics are two injection molders that serve the medical device market and will implement Mantle technology to reduce the time and labor required to make precise injection mold tooling components. These examples are featured in Mantle’s booth #3995 at the MD&M West conference taking place this week, Feb. 7-9, 2023, in Anaheim, California.

Nicolet Plastics, a Wisconsin-based full-service plastic injection molder, is adopting Mantle’s metal 3D printing technology to produce steel production tooling in prototyping time and to deliver molded parts to its customer more quickly.

“As an injection molder, Mantle allows us to bring additional tool production in-house and increase the complexity of the tools and inserts we manufacture,” Tony Cavalco, Nicolet Plastics CEO, says. “We will significantly reduce the time it takes to produce production-quality tools and be able to start production in weeks versus months.”

Nicolet Plastics recently used Mantle’s 3D printer to produce production tooling for its customer, Gamber-Johnson. By printing three inserts, Nicolet Plastics reduced toolmaker time from 180 hours to 12.5 hours and reduced the time to produce the first molded part samples from six weeks to two weeks. Mantle produced inserts that were 95% complete and required only minor finishing before molding began.

“We printed up the inserts … (and) did a little bit of final fitting here and there, and we were able to get it in the press and start molding parts relatively quickly,” Eric Derner, Nicolet Plastics, adds. “We only had about 10 hours worth of secondary operations and final fitting we had to do. Our toolmaker was … a little bit pessimistic, but when I came in that Friday to ask how everything went, he was almost jumping up and down with joy.”

Westec Plastics Corp., a full-service plastic injection molder in Livermore, California, is also adopting Mantle’s metal 3D printing technology to increase its tooling capacity without having to hire valuable but scarce toolmakers. Mantle has enabled Westec to quickly produce H13 inserts that are anywhere from 75-95% complete with minimal time from its toolmakers, freeing them up to focus on critical operations such as tool repair and maintenance.

When producing the tooling for a medical diagnostic housing, Mantle says its technology enabled Westec to cut the tooling cost in half by reducing the number of active operation hours on the inserts from 40 hours to just 10. The tooling cost was reduced while simultaneously freeing the toolmakers to work on additional projects. The tools were used to mold TPE.

“Tooling is the base of our company,” Tammy Barras, president, Westec Plastics Corp., says. “Without quality tooling, we can’t produce quality parts, but it’s getting harder and harder to find quality toolmakers. Using Mantle’s technology, we can complete up to 70% of the job, and have our toolmakers handle the specialized steps that only a human can do. We need to take advantage of this new technology. With Mantle, we can provide our customers a service they can’t get anywhere else.”

RELATED CONTENT

-

How to Deal with Graphite Dust, Part 1

A review of the characteristics and considerations when handling graphite dust.

-

Graphite vs. Copper Electrode Material for EDM Applications, Part 1

If you’ve been torn in the long-standing, unresolved debate over whether graphite or copper is a better EDM electrode material, here are some considerations identifying differences in cost, detail and performance to help you select the appropriate material for EDM applications.

-

Plastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.