This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Action Mold and Machining’s Additive Manufacturing Manager Greg Nemecek and Matt Duffey, Marketing & Advanced Development for AM previously discussed the strong connection between AM education and ROI, the team and technology that make up Action Mold & Machining’s additive capabilities, including their laser powder bed system and new young AM advocate in training, the company’s AM goals and recommendations for getting the entire team to buy into adopting AM.

Featured Content

Now we turn to the importance of having the capabilities to offer support to your customer beyond AM, the necessary facility and equipment requirements, and how AM in moldmaking is quickest return on investment.

This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Watch the full video chat above, access Part 1 of this MMT Chat here, and for more of our archived MMT Chat conversations, click here.

RELATED CONTENT

-

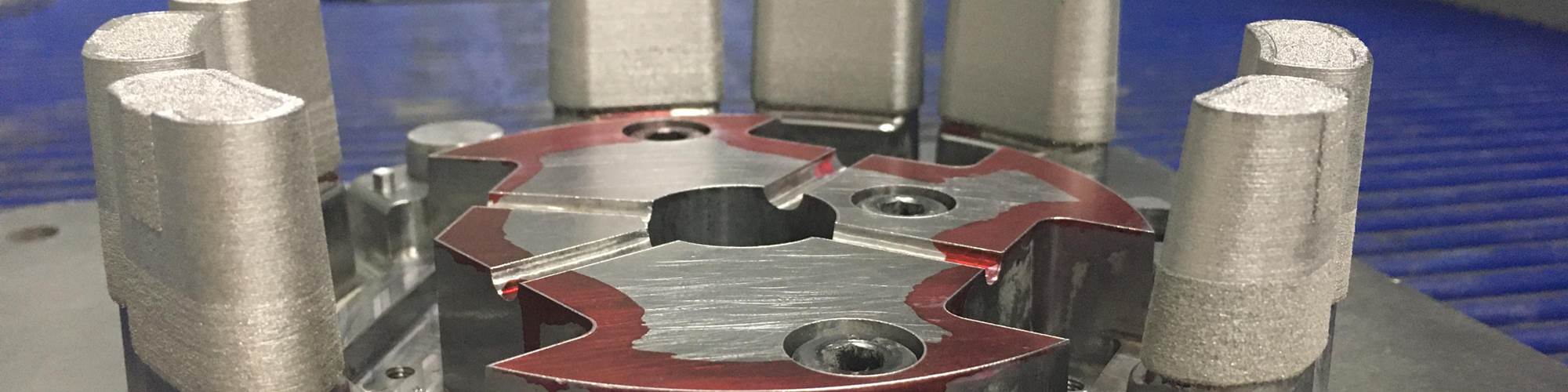

The Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D-printed parts.

-

VIDEO: Qualifying Modified H-13 for 3D-Printed Tooling

Next Chapter Manufacturing and International Mold Steel discuss their partnership to qualify a modified H-13 for tooling applications.

-

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.