Moldmaking Strategies Take on Surface Finish, Accuracy and Short Delivery Time Challenges

SolidCAM combines high-quality toolpath fidelity, surface finish, automatic toolpath updates and error-free G-Code for an ideal CAM solution.

#supplychain

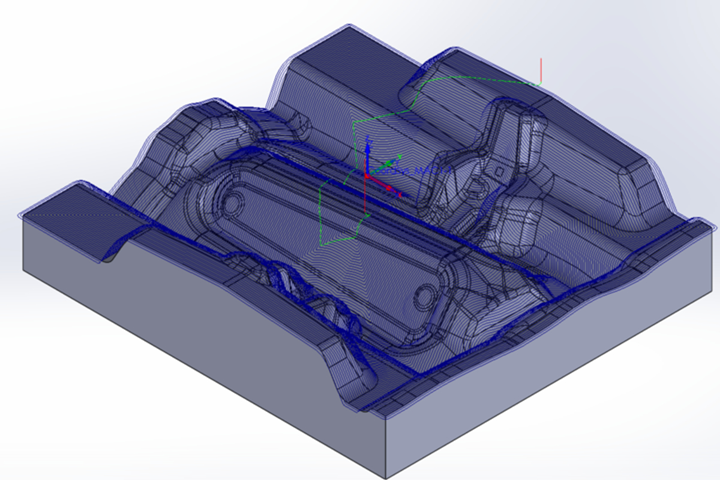

Photo Credit: SolidCAM

SolidCAM highlights its Integrated Solution, along with iMachining, as an ideal CAM solution for moldmaking.

According to the company, the main challenges for the industry are surface finish, surface accuracy and short delivery times. To meet these challenges, SolidCAM reportedly combines:

- Excellent toolpath quality/fidelity by working directly on the CAD model

- High-quality surface finish, and hard-material cutting performance from optimally controlled cutter-to-material contact

- The time-saving benefit of automatic toolpath updates for mold changes

- Error-free G-Code and the elimination of on-machine edits for first part success

SolidCAM notes its latest version also included enhancements to its iMachining 3D, HSM and simultaneous five-axis modules which combine mold and insert machining.

RELATED CONTENT

-

7 Key Advantages of Hot Runner Systems

While both hot runner and cold runner systems have their benefits, for design flexibility as well as reduced cycle times and costs, hot runner systems will probably be the better choice.

-

Tool Up with Rapid Heat/Cool Technology

A rapid heating and cooling technique using pressurized water solves sink, weld line and discoloration problems.

-

Exploring ISO 9000 -Part 14 Corrective and Preventive Action

A Series of International Standards for Quality Management and Quality Assurance