MoldMaking Technology’s profiles showcase interviews and narratives delving into professionals' experiences within the moldmaking industry. These stories offer valuable insights into their journeys, shedding light on the challenges, successes and innovative approaches that shape this sector.

We strive to highlight innovative approaches, success stories, challenges faced and solutions implemented by individuals or companies within the field. Topics may include technological advancements, best practices, industry trends and personal journeys of those making significant contributions to the moldmaking sector. Our hope is that these provide valuable insights and inspiration to professionals within the industry.

Featured Content

Here are our top five profiles of 2023, based on Google Analytics:

4. Specialist Automotive Mold Builder Mentors in Work and Life Skills

Troy DeVlieger, president of PFAFF Molds, shares insights into the company’s history, specialization, challenges and training philosophy. PFAFF, established in 1957 by Stefan Pfaff in Germany, has evolved into a global leader in supplying molds, automation and production equipment for vehicle body sealing systems. Despite opportunities to diversify, they remain focused on their niche market, collaborating closely with clients for custom solutions.

DeVlieger emphasizes the unique challenges of the industry, dealing with fluctuating workflows and complexities in rubber molds compared to plastic ones. The lack of a skilled workforce pipeline prompted PFAFF to integrate automation into their solutions, reducing the reliance on human labor while enhancing efficiency and profitability for their customers.

2. Next-Generation Thinkers Redefine Moldmaking Quality and Service

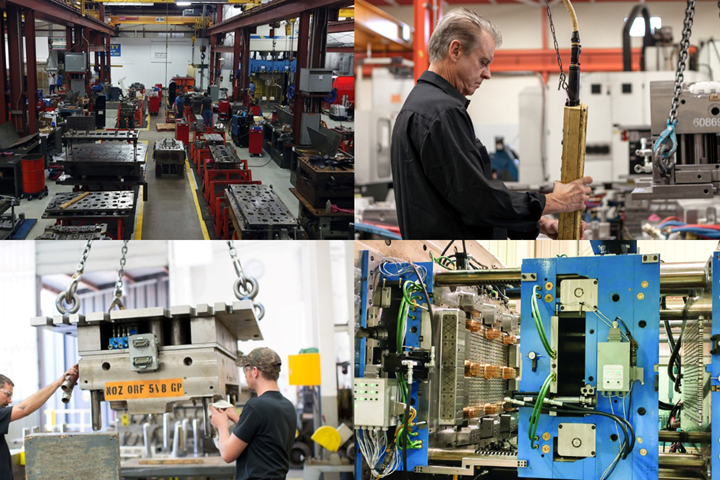

NextGen Mold Technologies, an innovative mold provider in the automotive industry, offers comprehensive services from concept to completion, repairs, engineering changes, and more. Founded by Dennis Goggin and Nicola Geyser, NextGen emphasizes quality, efficiency and a strong team.

Photo credit:NextGen Mold Technologies

Specializing in the automotive sector, they target interior and lighting Tier 1 markets. Goggin, with extensive experience in the industry, transitioned struggling businesses into profitable ventures, eventually leading to the establishment of NextGen Mold Technologies. Geyser, with a legal background, found her niche in HR, making a significant career shift into the mold industry.

Rather than starting from scratch, NextGen acquired Enterprise Mold, recognizing its untapped potential. Leveraging existing machinery and the foundation laid by the previous owner, they expanded operations and revamped the company culture, aiming to create an environment of growth and innovation.

Read more of MoldMaking Technology’s most-viewed content from 2023:

MoldMaking Technology's Hottest Tips of 2023

RELATED CONTENT

-

VIDEO: Simplify Mold Management of Your Tooling Fleet

In this digital demo, Progressive Components explains its basic asset management and mold monitoring system, ProFile, where it is possible to monitor all your assets in one place.

-

A Passion for Innovation in High-Precision, Multi-Cavity Moldmaking

Boucherie uses its dedicated R&D facility to develop new mold, machinery and automation technologies to stay ahead of the competition.

-

Poll: From Our Top 4 Most Popular Profiles Over the Past 25 Years, Which Was Your Favorite?

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=970;quality=90)