New Year, New Popular Articles from MoldMaking Technology

The top ten most-viewed articles in January reflected not only what our readers wanted to see—but also what is new and trending in moldmaking.

10. How to Use and Protect Remote Machine Monitoring Data

Manufacturing relies heavily on data analytics to enhance performance. Remote machine monitoring, which gathers and analyzes machine data in real-time, is crucial for identifying and addressing issues promptly. This article provides a comprehensive list of six key benefits of remote machine monitoring for moldmakers.

8. Innovative Mold Building Enhances Packaging Material Efficiency, Elevates Recyclable Design

The Beckman Coulter Diagnostics’ Global Plastics team needed a packaging solution seamlessly integrated with their DxI 9000 IA analyzer, minimizing material content and capitalizing on recycling opportunities. Beckman Coulter approached Plastic Ingenuity to partner on designing a custom thermoformed package to hold and protect 520 pipette tips in four rigid polystyrene trays. This article covers the trials and tribulations of that process.

Featured Content

6. What's So Cool About Manufacturing? Students Use a Camera to Find Out

DVIRC, a local manufacturing extension partnership (MEP) organization, is a private, not-for-profit entity that supports the growth of small- and medium-sized U.S. manufacturers, distributors and R&D labs. One way they do this is by supporting and growing the industry’s talent pipeline through the What’s So Cool About Manufacturing (WSCM) Program for the southeastern Pennsylvania region, sponsored by the H. Howard Colehower Foundation. The overarching goal of the WSCM program is to transform students’ perceptions of manufacturing and manufacturing careers through a video contest. Read more.

4. Electroform and Hononegah High School Partner for Hands-On Moldmaking Education

In another article addressing workforce development, Rockford, Illinois-based mold builder Electroform has partnered with Hononegah Education Manufacturing Connection (EMC) to promote manufacturing. More specifically, moldmaking and molding, by providing real-world, hands-on experience in manufacturing and engineering. Read more.

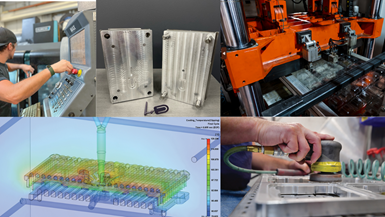

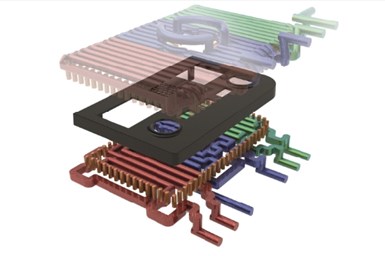

2. How to Use Simulation to Achieve a High-Gloss Surface Finish

Source: SimpaTec

Using process simulation early in a project, such as optimizing temperature control systems and comparing manufacturing methods, can streamline product development and manufacturing processes while achieving a high-quality, glossy surface finish for a part. Combining simulation, conformal cooling, and a rapid heat and cooling process can predict and produce the required surface finish for high-gloss plastic parts. Read more.

RELATED CONTENT

-

Using CT Scanning to Qualify Molds Faster

Software and hardware advances reduce dimensional inspection with part-to-CAD by 70%.

-

Software Strategy for Automated Mold Inspection

Consider inspection software with a CAD/CAM platform that supports model-based definition, works with all CAD files, and drives all fixed and portable CMMs.

-

CAM Automation, Hot Runners, Asset Management & More: The Best of August

What does CAM automation, hot runners, and simulation software all have in common? They are all topics that made it into our top ten most-viewed content pieces in August.