Editorial, News, and Products

End Mill Series Committed to High Hardness Steels

OSG USA AE-CR-MS-H end mill and Phoenix PXM-PXSH exchangeable head end mill series can machine steels from 50-70 HRC, a common range seen in moldmaking.

Amerimold 2021 Post-Show Flashback: Build

MMT looks back on the return of an in-person Amerimold in September after a year-long pandemic.

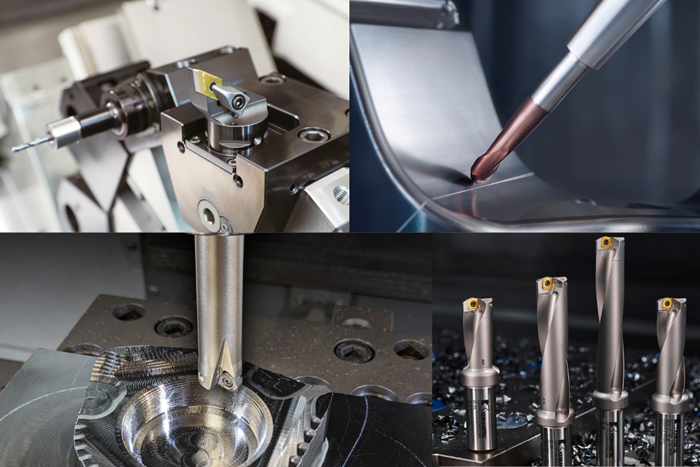

Why Mold Builders Should Consider Barrel Cutters and Lens Tools If They Haven’t Before

Reduce machining cycle times and improve surface finishes of cavity and core work with barrel cutters and lens tools.

End Mill Cutting Tools Optimized for Dynamic Steel Milling

OSG’s HY-PRO CARB VGM end mills and the A Brand AE-H advanced performance carbide end mill achieve longer tool life, optimum heat resistance and a host of other advantages.

Cutting Tools Ideal for Surface Accuracy

OSG USA Inc. releases two-flute high-precision finishing long neck carbide ball end mill series for high-hardness steels.

The Most Viewed Products of 2018

MoldMaking Technology wraps up the year by showcasing the most-viewed products of 2018.

Get Your “A Brand” On at OSG USA for a Chance to Win

OSG USA has brought its A-game to IMTS by putting a spotlight on its A Brand of cutting tools.

Accuracy and Surface-Finish Needs Drive Cutting-Tool Solutions

Cutting-tool suppliers are using advanced coatings, new thread designs, education and collaboration to help moldmakers maximize results.

2018 Technology Review and Sourcing Guide: Cutting Tools

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including cutting tools.

Drill Has Coating to Facilitate Chip Evacuation

The Exocarb ADF enables one-step drilling to simplify machining time and tool management.

Successful Supplier Nights Help "Mold" Careers

The Chicago Chapter of the American Mold Builders Association (AMBA) recently hosted its fourth successful supplier night fundraiser that continues to provide much-needed support for promoting careers in moldmaking.

Chicago Area Companies Give Students a "Tooling Start"

Moldmaking industry suppliers and shops support advanced manufacturing curricula in Chicago area high schools by donating products and scholarships.

OSG Announces “Shaping Your Dreams” Scholarship Winners

On February 7, 2018, OSG USA Inc. recognized the recipients of its inaugural “Shaping Your Dreams” scholarship program.

2017: Gone but Not Forgotten

I wish to thank everyone I’ve worked with to write features that have appeared each month in MMT. Plus, a look at a series of features about one of my favorite topics: Workforce development.

Top-Viewed Articles on MMT

Click through the slideshow to see which topics have been of particular interest to the MMT community over the years.

Supplier-Based Training Programs Fuel Mold Industry Needs

Moldmaking industry supplier companies establish workforce development programs to increase the flow of new talent for themselves and for the industry.

Manufacturing Day is an Opportunity for our Industry

How are you celebrating our national day, Manufacturing Day, this year? October 7 marks the fifth year since Manufacturing Day was established in the US, Canada and Mexico, and the mold manufacturing industry should embrace the opportunity to spread the message that moldmaking is cool!

Machining 3D Parts

For most of the 3D machining required in moldmaking, there are essentially seven steps necessary to achieve the desired results in terms of shape, finish and cycle time.

Amerimold 2015 Bringing You In-Depth Workshops

New this year, Amerimold Expo's technical conference program is offering two half-day workshops for a deeper dive into programming 3D parts and strategies for making mold maintenance profitable.

Cutting the Impossible

A new approach to machining deep 3D cavities and cores.

Think Metric, Part 3

Insight from several technology suppliers—in design software, mold components, programming, machines, cutting tools and measurement equipment who have been following the metric trend—may help to make the transition a smooth one.

Manpower, Machine Time Maximized with Highly Accurate VMC

“Using highly accurate machines allows more efficient utilization of manpower and machine time—saving time and money for the customer and making BPM more profitable.”

Machining Techniques: Are You Finished Yet?

Have you ever heard that question? People who work in the mold and die industry have probably heard it more frequently than they would like to; however, great strides in cutting tool and machining techniques in the last couple of decades are enabling more “Yes” answers.

Finishing and Roughing Strategies

This tool finish mills at high speeds in a wide range of work materials.

Cutting Tool Strategies for Milling Ribs

A review of machining options for tapered rib processing, typically found in plastic injection and die cast molds.

Going Green Can Garner New Business

Adopting green initiatives is not only important to your business, it is important to your customer and should be a part of your standard business practices.

Minimal Investment In New Tooling Tech Increases Productivity, Tool Life and the Bottom Line

Having a fundamental base of the facts makes it easier to detail how some of the latest innovations in cutting tool substrates, geometries and coatings can make it easier for one’s moldmaking process to go from fast to furious.

Machining Molds with Negative Stock Shutoffs

Negative stock shutoff can help you make better molds in less time. Here is a clear definition and description of the process. While the concept is fairly simple, the implementation can be challenging.

How to Choose the Right Tool Coating for Your Machining Application

Selection criteria and common coating attributes for PVD, CVD and other common coatings.

Applying cBN Technology to Moldmaking

A summary of cBN and its progression to a preferred substrate for high-accuracy hard milling.

Advanced Cutting Tools Translate To Greater Cost Savings

Increasing initial tooling investments will allow moldmakers take home more profits at the end of the day.