Injection Molding Process Control System Provides Traceable Data and Valve Gate Control

RJG showcases its CoPilot injection molding process control system, which is said to be user-friendly and enable users to collect traceable process data and now includes valve gate control.

#amerimold

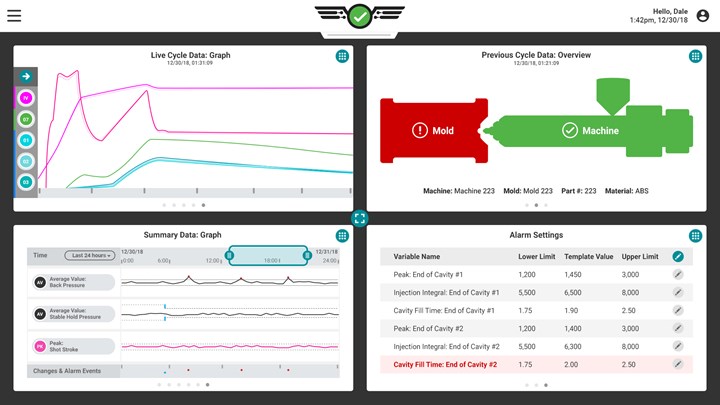

RJG’s CoPilot injection molding process control system is designed to be a user-friendly platform for producing high-quality parts. The CoPilot system enables users to observe what is happening to the part and identify when a process strays from the template, according to the company.

The system provides traceable data, which RJG says reduces risk. It also allows users to sort suspect parts, collect data to help identify the root cause of a problem and access data globally. The latest update enables in-mold temperature sensor users to set alarms on the summary variable temperature rise. Process templates can also now be archived from the cycle graph template menu.

RJG’s CoPilot process control system also now includes valve gate control. Users are able to employ in-cavity pressure or temperature sensors to control when the valves open or close, which is said to reduce the effects of material changes.

According to the company, benefits of using valve gate control include gaining precise, individual control of flow fronts in a large multi-gate cavity, in cavities making different parts and in cavities making the same parts where cavity fill balance is an issue; increased control over the removal or moving of knit lines; improved, long-term part consistency in both family and multi-cavity molds; and maximized uptime, process capability and performance.

Moreover, users are able to view a snapshot of how valve gates are functioning from the overview screen, RJG says. By clicking into the valve gate screen, users can get more detailed information, including when each specific valve gate opened, when it closed and if it didn't trigger.

Valve gate control is ideal for the following applications:

- Large, cosmetic, complicated parts that require multiple valve gates.

- Multi-cavity family tools with a gate for each cavity.

- Multi-cavity tools with a gate for each cavity.

RELATED CONTENT

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

Detecting Water Flow Restrictions

A look at how taking the time and data to analyze a mold problem will help you repair it right—and permanently—the first time.

-

Plug-And-Play Mold Monitoring Provides Transparent, Efficient Processes

A plug-and-play mold monitoring device, which takes intelligence into the tool without the complexity often associated with Industry 4.0, helps mold owners who continue to struggle with monitoring their molds.