Editorial, News, and Products

MMT Chats: California Mold Builder Discusses the Difficulties with Silicone Molding and the Power of the Magic 8 Ball

MoldMaking Technology Editorial Director Christina Fuges sits down with M.R. Mold President and Owner, Rick Finnie, to discuss how he began his moldmaking career, M.R. Mold's LSR Education, and the struggles of working with silicone. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Mold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Maintaining a Competitive Edge: EDM, Automation and Machining Technology Roundup

This month’s technology roundup features products, processes and services relating to EDM, automation and machining. For example, jig grinding for large molds, scheduling automation software, cobot integration, die sinker EDM and much more.

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Die-Sinker EDM Series Fits Needs for Enhanced Automation, Speed, Surface Finish

The Sodick ALG EDM series doubles motor response speed for the development of accurate, high-quality molds, and is equipped with automated features for continuous operations.

Rotating Wire Function Cuts EDM Wire Consumption, Optimizes Mold Cutting Conditions

Sodick puts a new spin on its ALN and ALP wire EDM line with a new function that reduce wire consumption by 25% and improve the geometric accuracy and surface quality of workpieces.

VIDEO: The Capabilities of Micro Molding

In this demo, Sodick IMM by Plustech shares its micro molding capabilities with Matrix Tool and M.R. Mold.

MMT Chats: Thriving on First-Off Projects … EV and Electronic Encapsulation Tooling

MoldMaking Technology Editorial Director Christina Fuges talks to Kevin Hartsoe, president of Neu Dynamics in Ivyland, Pennsylvania, about the company’s focus on the electric vehicle market, the key to its success, projects in the pipeline as well as supply chain and workforce challenges. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

2021 Leadtime Leader Award Winner: Westminster Tool—Perseverance with a Plan

Westminster Tool’s latest commitment to the plan—investment in new technologies, processes and capabilities, workforce development/training and sales & marketing—helped them edge out this year’s competition.

Linear Drive CNC Machine Designed for High-Precision Small Hole Drilling

Sodick recommends its five-axis K4HL CNC machine for applications that require the high-speed drilling of thousands of small, high-precision holes.

Die-Sinker EDM Enhanced With Discharge Control, AI Technology

Sodick’s AL G Series Rigid linear motor-driven die-sinker EDM includes “SP Power Supply,” “Arc-less 4 Circuit” and “LN Professional AI software” enhancements.

The Lean Dream Team: How to Achieve High-Cavitation, Critical Dimension Molds

Incorporating multiple automation technologies enables Industrial Molds to produce and repair highly complex, precision molds with a very lean team.

Shared Engineering Expertise Overcomes Design and Delivery Challenges

Collaboration on part and mold design between a molder and mold builder were vital to overcoming design and production challenges for a unique automotive project.

Sodick/Plustech Launches "Sodick and Friends" Virtual Webinar

Precision injection molding machine manufacturer, Sodick, is hosting a range of topics in its virtual webinar series to optimize your processes and better your manufacturing operations.

Combining Customized Software with CMM Reduces Production Bottleneck

In order to reduce downtime on its EDM and CNC machines when setting up new jobs, moldmaker Kavia Tooling turned to a coordinate measuring machine from Hexagon Manufacturing Intelligence to create an offline zero transfer system ahead of the manufacturing process for parts and electrodes.

Noteworthy News: Perks & Promotions

Whether it be its employees or its customers, the businesses in some of MoldMaking Technology’s latest news releases show appreciation through their perks and promotions!

Sodick Announces 2-Year Standard Warranty

EDM manufacturer Sodick revealed that it will now include a two year warranty standard for all premium model wire and sinker EDMs.

Sodick Launches New Direct Sales in Ohio

Machine tool manufacturer Sodick, Inc. has launched a new direct sales structure in Ohio.

Custom Mold & Design Chases Complex Mold and Production Part Projects with Top-of-the-Line Five-Axis, Screw, Mill/Turn, Additive and Molding Machines

Unique business model—with an eye on complex projects and an arsenal of machine technology to meet the required accuracy levels—raises the bar in mold and machined component manufacturing.

Sodick Hosts Mold Design Training

This two-day mold design training event will take place on May 1-2, 2019, at Sodick’s headquarters in Schaumburg, Illinois.

Large Sinker EDM with Linear Motor Drives Enables High-Precision Mold Features

Sodick introduces the AG200L, its largest sinker EDM at nearly 10 feet wide with a work tank 15-percent larger than the AQ20L.

Additive Manufacturing Workshop Program at NAIAS

The NAIAS event is drawing major OEM presenters.

MTD Micro Molding Makes Major Investments

MTD Micro Molding has invested 10 percent of its annual revenue to internal R&D projects that explore micro-molding capabilities.

The Impact of 3D Printing on Wire EDM

3D printing impacts wire EDM workholding, cutting conditions and machine tool specifications.

Linear Motor Drive on Sinker EDM Machine Speeds Productivity

Linear motor technology in a sinker EDM machine enables Action Mold and Engineering to burn faster, more efficiently and more economically with minimal maintenance.

IMTS 2018: Process,Technology and Service Advancements

Advancements in automation and digital manufacturing took center stage during IMTS last week, but developments in additive manufacturing, cutter technology, machining solutions, simulation software, EDM, laser technology and customer service were other hot items.

Automation and Connectivity Drive Machine-Tool Innovations

Machine tool and EDM suppliers are advancing their offerings to include automation, better controls, machine monitoring and new five-axis capabilities.

Innovation Abounds at NPE2018

Here is a review of some notable moldmaking innovations and advancements on display at NPE2018.

Moldmaking on Full Display at NPE2018

Collaboration is the name of the game, as more than 60 North American mold builders showcased their capabilities in shared demonstrations across the show floor.

2018 Technology Review and Sourcing Guide: Additive Manufacturing

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including additive manufacturing.

2018 Technology Review and Sourcing Guide: Machining

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including machining.

2018 Technology Review and Sourcing Guide: EDM

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including EDM.

Sodick Celebrates the Grand Opening of its North American Headquarters

Grand Opening for VIP’s with a Japanese flair showcases Sodick’s new machining and 3D printing technologies.

NPE2018 Video Recap: Exhilaration, Innovation and Inspiration

MoldMaking Technology’s editorial team recaps some highlights from the show floor at NPE2018, including a technology slideshow, seven podcasts recorded live from the event and a video.

Toggle Design on Molding Machine Saves Time and Energy

Sodick’s first all-electric V-Line machine has 100-ton clamp with improved toggle design.

Sodick Welcomes New Member to Its Marketing Team

Sodick announces the addition of a new hire to its marketing team.

Successful Supplier Nights Help "Mold" Careers

The Chicago Chapter of the American Mold Builders Association (AMBA) recently hosted its fourth successful supplier night fundraiser that continues to provide much-needed support for promoting careers in moldmaking.

Demonstrations Highlight Course Opportunities and More

RJG Inc. holds multiple live demonstrations of its products on an injection molding machine in its booth.

Metal 3D Printer Combines Laser Sintering and High-Speed Milling

Laser sinter metal powder and perform CNC machining of tooling components in the same machine.

Micro-Mold Demonstration Highlights Collaboration

Mold Craft Inc. demonstrates micro-injection molding NPE2018 with a Wittmann Battenfeld press and a Sodick vertical molding machine.

Stand-Alone Additive Manufacturing Is a Thing of the Past

Additive manufacturing (AM) is no longer considered a stand-alone technology but is increasingly being integrated in existing manufacturing processes.

Sodick Announces Completion of New Headquarters Building

Northern Builders Inc. completed the building for Sodick Inc. It incorporates Feng Shui and is highly visible from I-90 in Chicago, Illinois.

EDM Machine Has High-Column Design for Work on Large Molds

The VL600QH EDM unit from Sodick Inc. has a 500-mm Z-axis stroke to accommodate large work pieces.

Technology Tuesday: EDM Success

Cruise through this week’s Technology Tuesday slideshow to see EDM units that shops across the country have used to increase capacity and leverage greater efficiency in their processes.

Technology Tuesday: The Latest Products

Cruise through this week’s Technology Tuesday slideshow to see some of the latest products.

Technology Tuesday: Featured Films

Pass the popcorn, please! This week’s Technology Tuesday slideshow is all about videos that have supplemented feature articles and case studies in MoldMaking Technology over the past year.

Horizontal Injection Molding Machine Has Plunger for Consistent Measurement of Melt Stream

Plustech, Inc., the North American Branch of Sodick, Inc.’s IMM Division, now offers a line of two-shot machines that are additions to the already existing GL Series, horizontal injection molding machine line.

Fun Friday: The Moldmaking Community Shows Patriotism, Heart and More

On September 15, 2017 our team at Alliance Specialties and Laser Sales partnered with our friends Tim and Kim Bartz from iWarriors and Mold Craft to host the inaugural Alliance iWarriors Charity Golf Outing.

SLIDESHOW: Technology Tuesday, Technology in Action

This week, instead of a showcase of static product information, I thought I'd share some videos demonstrating technology in action that MMT has covered.

Laser Optimization Brings AM to the Next Level for Moldmaking

Metal 3D printer manufacturer Sodick first launched its OPM250L at IMTS 2016, where Phoenix DeVentures of Morgan Hill, California, showcased its success with the new hybrid machine.

Bigger, Faster EDM Capacity Yields Growth

This Wisconsin shop recently fortified its EDM capabilities with the purchase of four new EDMs that offer larger axis travels, faster cutting capabilities and reduced electrode usage.

EDM Features Longer Travels, Improved Wire Threading

Sodick's latest wire EDM, showcased at a recent open house event, also features linear motors, custom base ceramics and other features common to the company's entire line.

New Era, Same Winning Formula

This company succeeds by staying up-to-date on technology and being willing to do a bit extra in the name of customer service.

Slideshow: EMO 2015

Here are some highlights from this year's event.

All According to Plan

This moldmaker influences its own destiny by staying true to itself, knowing exactly where it wants to go, and ensuring everyone in the organization understands how to get there.

Controlling Costs by Controlling Production

A process-driven manufacturing strategy and extensive data tracking have enabled this company to double down on the advantages of integrated toolmaking and molding capability.

Streamlining Setups at Seescan

In addition to new equipment, this captive shop’s transformation involved implementing strategies to make the most of existing resources.

Breaking Barriers Between Vision and Reality

For this OEM, speeding time to market required empowering its captive moldmaking operation with not only new technology, but the culture to use it effectively.

2014 Leadtime Leader Awards Winner: Westminster Tool Inc.—Bridging the Gap without Losing Focus

A strong sense of self and a focus on people enabled this mold manufacturer to rapidly expand pre- and post-manufacturing services without getting overwhelmed by its own growth.

Maintaining High Levels of Initial Machining Accuracy

While planning for the future, Mold Craft is disposing of less capable equipment taking up valuable floor space and replacing it with profitable, state-of-the-art machines, such as its latest investment.

New Tech for the Mold Shop

I’m not sure how many moldmakers attended Sodick’s “Smart Technology” open house in Schaumburg, Illinois last month, but the offerings unveiled at the event were particularly relevant to our corner of the industry.

Traditional Labor Values Meet Linear Technology

What GW gained was high reliability, improved speed/throughput without sacrificing accuracy or quality and a high level of satisfaction from the operators, on all the machines.

Dedicated Electrode Design Module Revolutionizes Copper Electrode Production

A tooling manufacturer says the combination of a new Sodick EDM AG60L spark eroder and switching to Vero Software’s dedicated electrode design module, VISI Electrode, has completely revolutionized the production of their copper electrodes.

EDM Efficiencies Excel

Advancements in EDM processes in terms of machining speed and surface finish improve overall accuracy, productivity and profitability.

From the Field: The Right CAD/CAM Makes New Mold Manufacture Easier and the Entire Process More Efficient

Fine, tiny detailing demanded by model railway enthusiasts requires moldmaking tolerances in manufacturing scale models that are often tighter than those in the automotive industry. With the right CAD/CAM system creating the mold around the designed product takes approximately 30% less time than it did with the CAD/CAM system PECO used before switching to VISI.

Leadtime Leader Takes on a Challenge

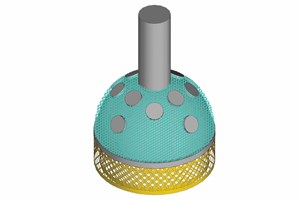

Can you really mold a pipette shaped part with a .015” wall x .370” long followed by a .008” wall x .080”? How about if the molding material is PEEK? How about 4 cavities? Can a Cpk of 1.33 be achieved on this wall section? These are the challenges and questions Mold Craft set out to prove the viability by partnering in flow simulation and press selection while Mold Craft designed and built a mold required for this difficult part.Although Mold Craft is typically known for their ability to design and build high cavitation production molds to produce parts that number in the hundreds of millions, Mold Craft has also received recognition for the ability to mold extremely tight tolerances on micro parts with intricate geometry that require high Cpk values. This challenge was just that, micro parts shaped like a funnel or pipette with extreme length to wall thickness ratio. To add to this complexity, the customer needed to use PEEK due to its high strength characteristics.Mold craft will be displaying their latest mold in the Sodick Plustech press at NPE in Orlando. Mold Craft (booth 1295) will have the attached photographed mold operating at Sodick Plustech booth 363.Read full story here.

Mold Craft Tool Showcased Sodick Plustech’s New Micro Molding Machine

A 4-cavity mold for very small PEEK parts—a pipette “funnel tip” component for a medical customer—ran in the new Sodick Plustech LP20EH2 Micro Molding series with a 12-mm diameter plunger.

Three EDM Warranty Considerations

Some factors to consider when purchasing a warranty program with your new EDM: price, benefits, time and preventive maintenance.

Two-Stage Plunger System

See Us at Booth #363

Diversity Is Key to Over Six Decades of Moldmaking Success

In 1945, George Carson dreamt of owning his own business. So he founded Carson Tool & Mold (Kennesaw, GA) in his garage, and hired his first employee—George Myers. Carson ran the shop until he retired in 1988 and Myers continued to build the business, passing the reins to his son David, who currently serves as president after purchasing the company in 1996.

Sinker and Wire EDM

Sodick Inc. (Schaumburg, IL) will be featuring its latest innovative technology at Eastec 2011, including the AG40L Sinker EDM and the AG600L Wire EDM.

2011 Leadtime Leader Awards: Small Shop Winner

Mold-Tech, Inc.: Technology-Driven, Detail-Oriented Precision Injection Mold Provider.

High-Speed Mill Keeps Tight Tolerances, Increases Efficiencies

Busy moldmaker turns to HSM to boost productivity and remain competitive in both the domestic and foreign arenas—and realizes time savings of up to 60 percent.

Synergetic M2M Group: A Global Presence

Overseas operations in more than 10 countries solidifies this moldmaker’s place in the world and earns them the MoldMaking Technology 2007 Leadtime Leader Honorable Mention: Large Shop.

Tech Tool & Mold, Inc.: Strength and Flexibility

This moldmaker garners the 2007 Leadtime Leader Award: Small Shop by being flexible with its customers, going lean, competing globally and uniting with other moldmakers.

Precision Manufacturing Institute: Specialized Training

This school works hand-in-hand with suppliers and shops—relying on their expertise and input to stay on top of industry trends and help develop a tailor-made curriculum in precision machining and moldmaking.

Linear Motor Technology for CNC Die Sinker EDMs - From the Operator's Perspective

Linear motor EDM technology provides great advantages for today's EDM operators. It not only makes the lives of EDM operators productive and efficient, it also opens up new worlds of possibility for product planning.