Editorial, News, and Products

How to Lower Cycle Times With the Right Tool Steel

Combining excellent mechanical properties, high wear resistance and high thermal conductivity in a specialty tool steel yields cycle time reduction.

Advancing the Mold With New Technologies

This roundup is full of products and services that help answer concerns and meet needs for the industry. Featured in this roundup are hot runners, mold components, mold materials and more.

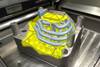

Hot Work Tool Steel Achieves High Thermal Conductivity

Developed by Deutsche Edelstahlwerke, a member of Swiss Steel Group, Thermodur 2383 Supercool combines high wear resistance with excellent mechanical properties for noticeably lower cycle times in molding/forming applications.

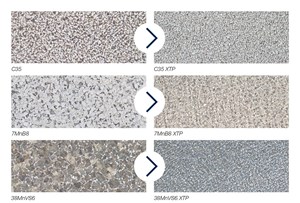

Corrosion-Resistant, Highly Machinable Tool Steel

Opticut mold steels from Swiss Steel Group member Deutsche Edelstahlwerke apply a novel treatment to the material to eliminate the deterioration caused by the addition of sulfur.

Swiss Steel Highlights Specialty Steel Material for High Corrosion Resistance

Amerimold 2021 exhibitor Swiss Steel offers Corroplast, a stainless steel mold base material for use in high-humidity environments and with corrosive resins.

From CAM, Cutters and Cooling to Corrosion, Cleaning and Control

A review of the year’s top tips on technologies and strategies to improve moldmaking operations from design to first shot.

Steel Choice Matters for Corrosion Resistance

A free-machining stainless steel faces the extremely corrosive injection molding environment head on, improving machinability and stability.

Association Update: American Mold Builders Association

The American Mold Builders Association and its Chicago and West Michigan chapters announce 2018 achievements and 2019 events.

How to Avoid Tool Steel Corrosion

A mold builder should consider corrosion resistance, hardness, machinability, processing, polishability, operational environment and wear resistance during tool steel selection.

The AMBA Chicago Chapter Recognizes Top Apprentices

At its December 4, 2018 Chapter Meeting, the AMBA Chicago Chapter recognized seven apprentices whose employers nominated them for the annual Mold Your Career Award.

2018 Technology Review and Sourcing Guide: Mold Materials

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including mold materials.

Co-Display of Mold Materials Features Wear Resistant Products

Finkl Steel and Schmolz + Bickenbach USA co-present a spread of mold materials at NPE2018.

Performance and Price Drive Developments in Mold Materials

Mold material suppliers are working to develop new, improved mold-material grades that will deliver on customers’ need for machinability, toughness, thermal conductivity and price.

Honoring Apprentices Builds Morale, Pride in Moldmaking

Last night I had the pleasure to attend the American Mold Builders Association (AMBA) Chicago Chapter dinner meeting, during which six young apprentices were honored by the mold shops that employ them via a nomination, submitted by their supervisors, for the chapter’s Mold Your Career Award.

The Economics of Metric

Why pay extra for inches when world economics is moving the U.S. into the metric age. Will this motivate the U.S. to convert in the next two years?

"Mold Your Career" Apprentice Award

Earlier this year we explained the origin and purpose of this Award established by the AMBA Chicago Chapter--to recognize outstanding apprentices and assist them in acquiring the tools they need to effectively perform their jobs--but today we announce this year's winner.

Tackling Wear with Vacuum Heat Treating

This heat-treatment process provides critical temperature and wear-resistance properties to certain mold steels.

Tool Steel and Aluminum Staying Strong

A roundtable of mold material suppliers discuss how new offerings result in easier machinability, better weldabilty, increased strength and improved surface hardness.

Specialty Mold Steel

Corroplast FM.