Technologies for Maintaining, Repairing and Surface Treating Your Molds

This technology roundup covers everything from laser repair and mold protection coatings to in-house maintenance services and education tools for learning best practices behind taking care of injection molds.

Edited by

Photo Credit, clockwise from top left: Progressive Components, Mold Surface Textures, PCS Company and Boride Engineered Abrasives

Mold maintenance, repair and surface treatment is crucial to keeping molds healthy, functioning and performing at their best. Regular maintenance prevents wear and tear, reducing the likelihood of defects in manufactured parts and minimizes downtime. Repairing molds promptly safeguards against potential flaws, sustaining accuracy and reduces production interruptions. Surface treatment techniques like polishing or coatings improve mold durability, reduce friction and enhance part release, contributing to higher quality finished products and increased operational efficiency in the long term. These practices collectively preserve mold integrity, ensuring reliable and consistent performance throughout their lifecycle.

This technology roundup covers everything from laser repair and mold protection coatings to in-house maintenance services and education tools to learn the best practices behind taking care of injection molds. Every month, MoldMaking Technology’s roundups aim to streamline the process of discovering new product, process or service solutions to keep you in the loop of new developments that may be the perfect fit for your moldmaking operations.

Featured Content

To check out tech roundups from months prior, please browse the “New Tech” section of the MoldMaking Technology website, or look up “Technology Roundup” in the homepage Search bar. For more information on a product featured below, click on the title link for the respective product.

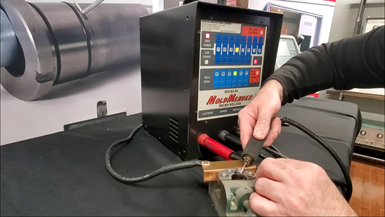

Photo Credit: Rocklin Manufacturing Co.

Portable, Low-Heat, Non-Arcing Resistance Welder for Mold Repair

Rocklin Manufacturing Co.’s MoldMender Micro Welder is a compact, handheld device that delivers simple and cost-effective mold and die repair in-house through a low heat, non-arcing welding process, ensuring controlled, localized repairs.

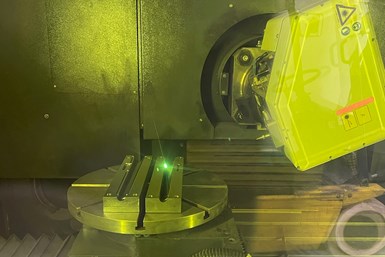

Intuitive, Maintenance-Free Laser Welder for Mold Repair

For mold builders, Gesswein showcases the SWA Fiber series of Sisma’s top-of-the-line laser welder, offering maximum working range to perform repairs and modifications on molds of any size, large or small. Powered by newly advanced technology, the solution’s fiber laser source offers greater energy efficiency for high productivity and reduced shop downtime.

Photo Credit: Progressive Components

Monitor Tool Wirelessly Tracks Mold Activity

The CVe Monitor RT from Progressive Components enables users to view the tool’s cycle count and other data on the device, provides Bluetooth access to information using the ProFile app and, with additional hardware, can send real-time data to the ProFile app in the cloud for global access.

Rust Preventatives Ensure Complete Mold Protection

Mold Shield Rust Preventive Spray (42910P) from Slide Products is a distinctive dry formula that protects against fingerprint acids and seals out condensation. This non-silicone, non-wax spray can armor molds for up to two years. It delivers a non-penetrating mist into ejector pin sleeves, slides, cams and other moving parts while displacing water condensation and unwanted residue.

Photo Credit: Blue Wave Ultrasonic

Blow-Off Station Adds to Ultrasonic Cleaning Effectiveness

Blue Wave Ultrasonics manufactures ultrasonic cleaning systems and user-friendly detergents specifically designed for cleaning injection mold tooling. These systems provide a powerful, microscopic scrubbing action that effectively removes outgassing residues, release agents and grime from even intricate, hard-to-reach areas such as details, ejector pin holes and vent channels, all without abrasives that can damage molding surfaces.Blue Wave continues its customer-forward innovation with the release of an integrated Blow-Off Station as part of the company’s Three Stage Clean, Rinse and Rust Inhibit cleaning systems.

RELATED CONTENT

-

3D Scanning Quickly Solves Tool Repair Problems

3D scanning supports the repair of molds with no history, drawings or design files.

-

The State of Maintenance: Where Are You?

New products, equipment and software are beneficial to mold maintenance, but they do not change the fundamental way a repair technician performs the job if the culture remains reactive. Is your toolroom reactive or proactive?

-

PTXPO 2023 Preview: Unlocking Your Next Solution for Mold Maintenance, Repair and Surface Treatment

PTXPO 2023 houses exhibitors that are ready to provide services and solutions for mold maintenance, repair and surface treatment challenges.