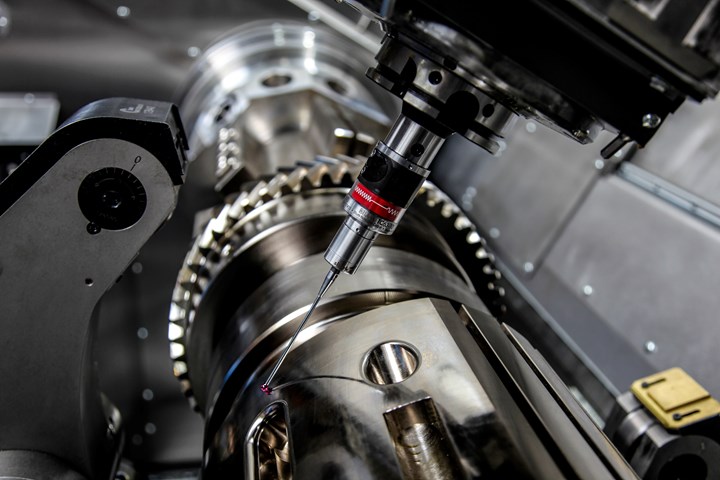

Touch Probe Delivers Fast, Precise and Reliable Mold Inspection

High scanning and probing speeds and a high-precision measuring mechanism characterize Blum-Novotest’s Digilog test probe systems.

Blum-Novotest, a manufacturer of innovative, high-quality measuring and testing technologies, features its Digilog test probe systems that enable high scanning and probing speeds in the hard-use, high-output molding environments. Complex contours can be monitored in series at up to 2 m/min to increase productivity while maintaining strict specifications.

Digilog TC63/64/76 probes provide high-precision digital measurements and lightning-fast analogue scans, according to the company. They feature BRC radio technology and are particularly suited for mold inspection. By analogue scanning the workpiece surface, machining errors are quickly and reliably detected. Shark360 technology, a high-precision, face-geared measuring mechanism, delivers defined deflection direction and constant deflection forces for maximum accuracy. The TC63 Digilog probe is the modular version that enables extensions and elbows attachments. The TC76 Digilog is a hard-wired alternative.

RELATED CONTENT

-

High-Precision Touch Probe for Grinders/Lathes Enables High-Accuracy Molds, Components

Increasing probing speeds and low probing force make the highly accurate TS 750 touch probe from Heidenhain reliable for even soft and delicate workpieces.

-

Fast, Precise and Reliable Touch Probe Systems Target Mold Inspection

Blum-Novotest demonstrates its TC63, TC64, and TC76 Digilob touch probe systems at IMTS 2022.

-

Surface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.