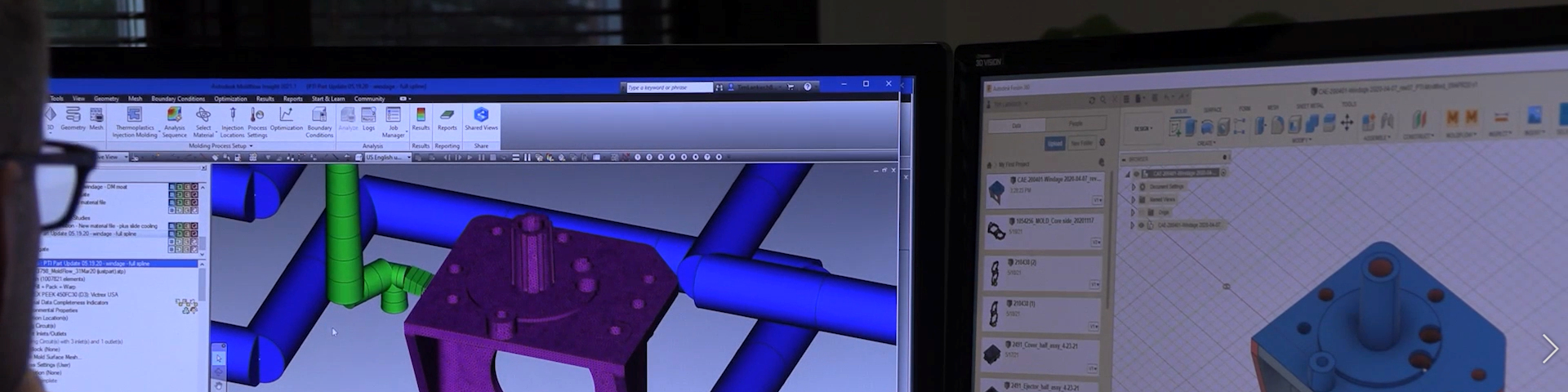

CAE discusses Moldflow simulation analysis, when a shop should outsource vs. invest in software and the mold builder’s role in mold analysis. They also go into detail about the importance of windage and morphing analysis as an accurate predictive tool when tolerance issues are a concern.

Chapters:

0:00 Introduction

Featured Content

3:08 When does a shop know whether to outsource or invest in software?

4:19 What is the mold builder's role in using the software?

7:00 The importance of windage and morphing analysis

9:55 Getting in the door

11:40 Why is cooling analysis valuable?

14:29 What is next for CAE?

For more video content from MMT, visit https://www.moldmakingtechnology.com/videos

RELATED CONTENT

-

When It Comes to Shop Safety, Think Beyond Pallets and Blocks

More often than not when touring a shop I see a unique approach to solving an everyday problem. This time it was a shop full of big, heavy molds that were not sitting on pallets or blocks across the the floor. Instead, they were sitting on top of small, plastic feet.

-

ICYMI, MMT Chats: 30 Under 30 Honoree, Plastics Engineering TA Teaches Value of Learning and Producing Not Perfection

MoldMaking Technology Editorial Director Christina Fuges brings on UMass Lowell Plastics Engineering Teaching Assistant Michael Shone as a guest for this MMT Chat to discuss moldmaking through the lens of academia. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

VIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.