Maraging Stainless Steel Powder Engineered for Additive Manufacturing Applications

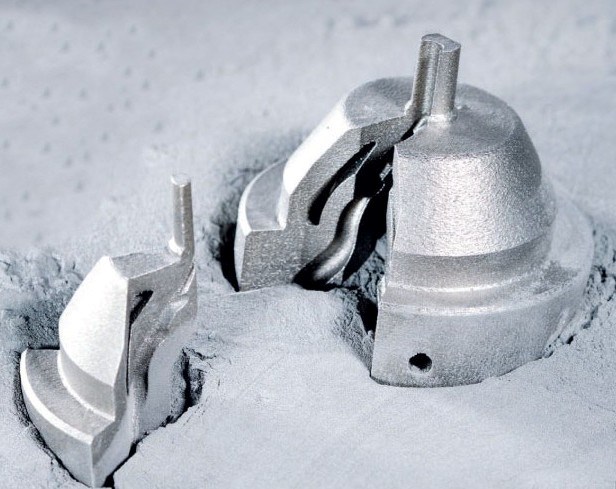

Bohler M789 AMPO, introduced by Edro Engineering, is well suited for conformal cooling inserts, or applications where high hardness and corrosion resistance is required.

Photo Credit: Edro Engineering and Specialty Steels LLC

Edro Engineering and Specialty Steels, an exclusive distributor of Bohler tool steels, highlights Bohler M789 AMPO, a newly developed maraging stainless steel powder designed for additive manufacturing (AM) applications.

Bohler M789 AMPO combines the mechanical properties of maraging 300 steel with the corrosion resistance of 17-4 PH stainless steel. Edro says the patented grade can be easily printed without preheating and can achieve a high hardness of 52 HRC with easy heat treatment. Bohler M789 AMPO also has excellent polishability which makes it the ideal choice for conformal cooling inserts in plastic injection molding and in any other application where high hardness and corrosion resistance is required.

For more information please visit Edro.com.

RELATED CONTENT

-

A Different Approach to Mold Venting

Alternative venting valves can help overcome standard mold venting limitations and improve mold performance.

-

Why Choose a Valve-Gated Hot Runner?

Moldmakers need to be aware of how different gating technology can affect their customers when designing a hot runner system into a mold.

-

Plastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.