Outlook for Automation in 2024

I want to share an article I found that discusses the reasons manufacturers should adopt automation in 2024 as a strategic response to global uncertainties, reshoring requirements, labor shortages and the pursuit of increased productivity.

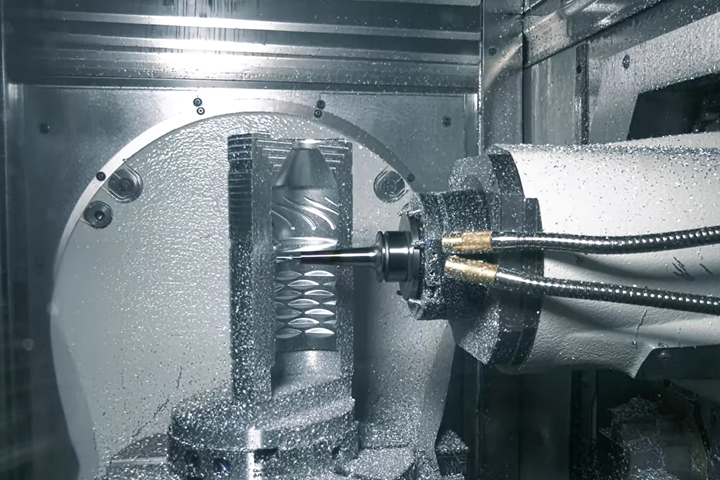

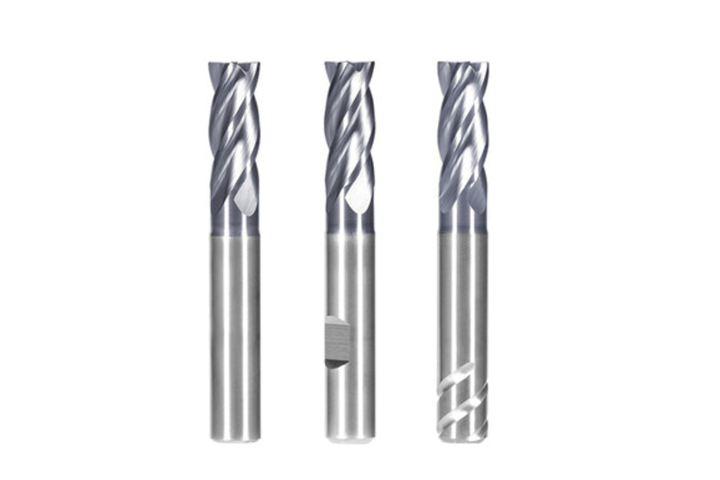

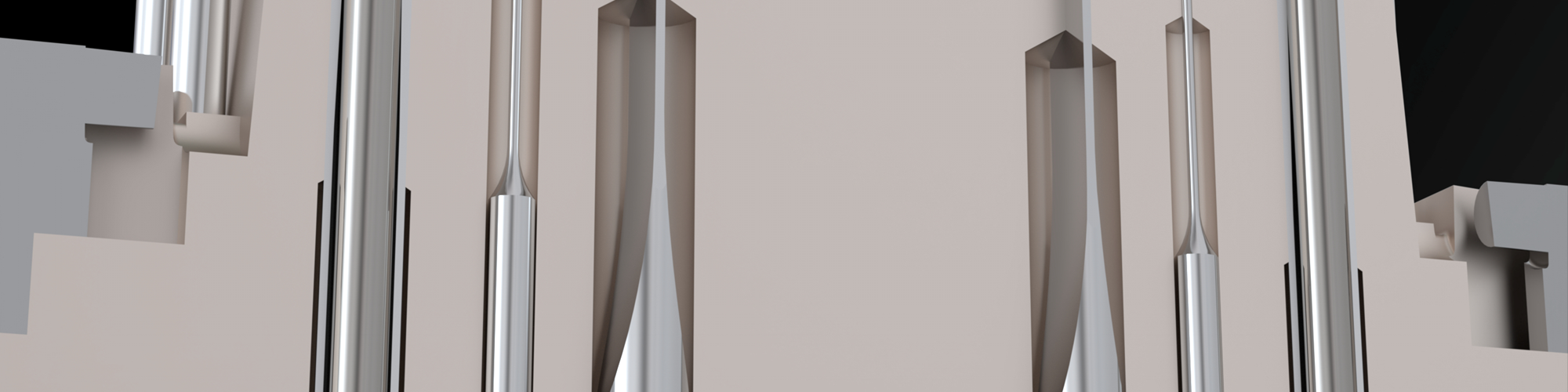

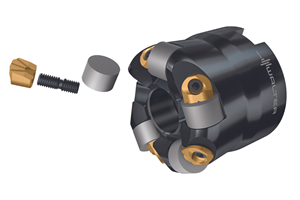

Collet Chuck Design Optimizes Machine Tool Performance

Lyndex-Nikken offers SK collet chucks with accuracy and precision in mind when milling, drilling, reaming and rigid tapping.

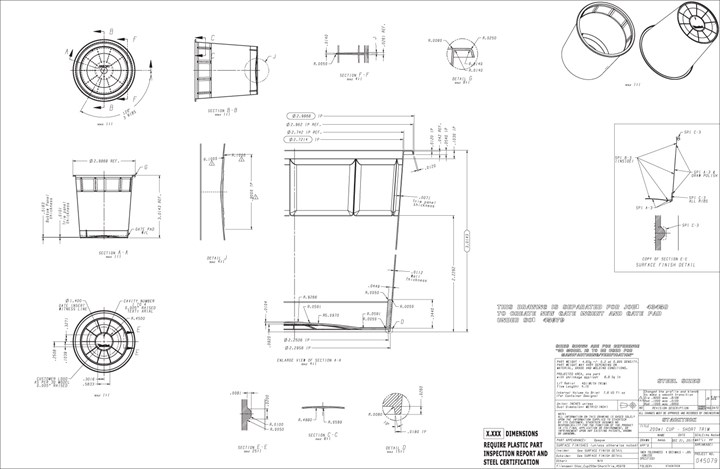

Maraging Stainless Steel Powder Engineered for Additive Manufacturing Applications

Bohler M789 AMPO, introduced by Edro Engineering, is well suited for conformal cooling inserts, or applications where high hardness and corrosion resistance is required.

Automation-Ready Nondestructive Inspection CT Systems

Nikon Metrology has launched VOXLS 30 C 225, 30 C 320 and 30 C 450 inspection models designed for automated operations across the production sector.

.jpg;maxWidth=970;quality=90)