Mold and Die End Mills Target Hard Machining

More than 20 new options in Emuge-Franken’s hard-cut ball nose and torus end mills line offer up to 60% longer tool life and excellent surface finish when roughing, pre-finishing, finishing and high-speed cutting.

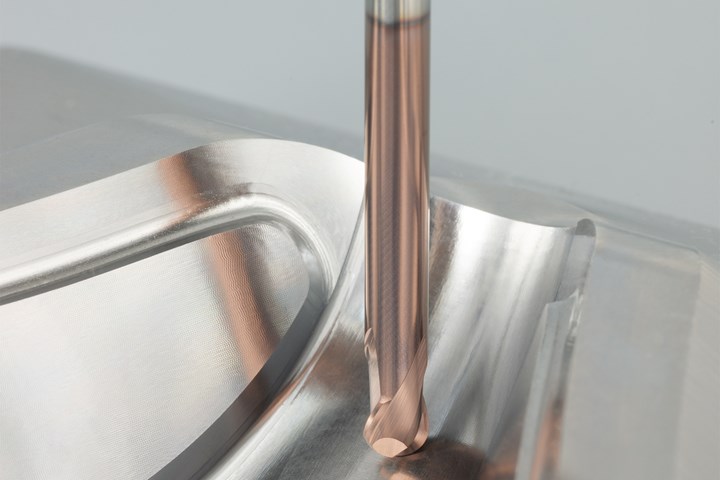

Emuge-Franken’s line of hard-cut ball nose and torus end mills line offer significantly longer tool life, and optimal surface finishes in hard materials.

More than 20 new solid carbide end mills in the hard-cut ball nose and torus line provide high-performance milling in materials hardened up to 66-70 HRC, as well as in unhardened steel and cast materials. Due to optimized tool geometry and high-performance solid carbide construction, the end mills offer up to 60% longer tool life and produce the highest quality surface finishes, according to the company.

Specifically optimized for hard machining including roughing, pre-finishing, finishing and high-speed cutting applications, Emuge-Franken’s end mills feature new precision cutting edge geometry and concentricity, and have a tighter h4 shank tolerance. The ball nose end mill has a diameter tolerance of -0.014 mm and a radius tolerance of -0.007 mm, and the torus end mill has a diameter tolerance of -0.015 mm with a radius tolerance of ±0.005 mm. A TiAlN tool coating, which indicated high performance in internal and customer testing, significantly extends tool life.

RELATED CONTENT

-

End Mill Series Design Enables Dynamic Milling Strategies

M.A. Ford’s TuffCut XV series of XV5CB, XV7 and XV7CB end mills get the job done when it comes to improving speeds and feeds, wear and surface finish, in addition to standing up to difficult-to-machine materials.

-

End Mill Grade Features Advanced Wear, Oxidation Resistance

Moldmakers can expect easier wear identification and longer machining capabilities using Kennametal’s latest KCSM15A solid carbide end mills.

-

Versatile End Mills Key for Moldmaking Operations

Said to be impossible to clog, the new series of Pow-R-Feed M936 cutting tools from IMCO Carbide Tool delivers free cutting at fast part cycles and high speeds and extended tool life in die steels.