Mold Software Gives Shops a Proactive Approach to Maintenance Tracking

MoldTrax releases feature updates to its MTLinX documentation tracking system to ensure your shop’s molds are running as efficiently and reliably as possible.

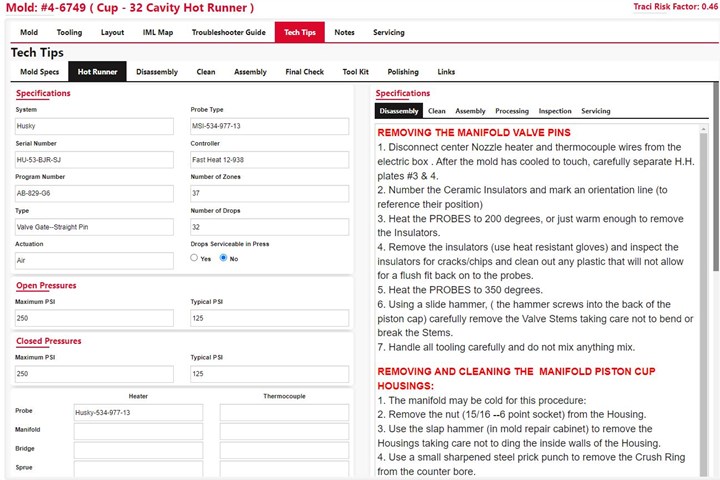

MoldTrax LLC presents MTLinX, the newest version of its popular documentation tracking system. MoldTrax contends that MTLinX is the only mold maintenance program created specifically for efficient tracking of the performance, maintenance efficiency and repair costs of injection, rubber, blow and die-cast, stamping, cutting and forming dies. MoldTrax’s distinctive architecture enables the use of a shop’s standard terminology throughout the system instead of typical, confusing journal entries that conventional systems may use.

One new feature is MTLinX’s expanded global version, which allows an OEM the visibility and tools to independently manage multiple molding locations around the globe through one database, and in eight different languages.

MTLinX users can also now connect their ERP, press or other processing systems for seamless data entry. Moreover, they now have the ability to set four levels of preventative maintenance (PM) based on cycles or calendar dates. An expanded PM “Alert” module shows approaching or overdue PM’s (green, yellow or red) in live time using cycles, hours and days.

An expanded Hot Runner section now includes instruction fields for disassembly, cleaning, inspecting and tracking hot runner components and the ability to “link” to outside sources for images and ordering replacement components

Finally, the MTLinX Mold Performance Dashboard automatically displays a shop’s top 10 frequencies and costs for tooling, labor and quality issues in one facility or across all its molders.

RELATED CONTENT

-

Rust Preventatives Ensure Complete Mold Protection

Slide Products highlights its line of oil-based and liquid rust preventative solutions, recognizing the necessity of regular maintenance for smooth mold-related operations.

-

Mold Maintenance Training Courses Teach Mold Management, Upkeep

Five comprehensive courses are available through Beaumont’s AIM Institute, which is also creating a new Mold Maintenance Center of Excellence in 2024 for additional education and training opportunities.

-

Intuitive, Maintenance-Free Laser Welder for Mold Repair

Reduce your shop downtime and get your molds back up and running in record speed with Sisma’s SWA Fiber laser welders, backed by Gesswein support.