Each month, MMT’s editors find inspiration in your diverse and varied interests. From mold design tolerancing to cutting tools and more, you, our readers, engage with a wide range of topics. One of our primary goals is to also keep you informed about the latest news and products (such as the SPE Mold Technologies Division, which garnered significant attention). Below are May’s top 10 most-viewed articles, per Google Analytics.

10. MMT Chats: Looking to Reinvent the SPE Mold Technologies Division

The SPE Mold Technologies Division chair breaks down all of the society’s current initiatives. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Featured Content

9. VIDEO: Maintaining a Customer-Centric Culture

Progressive Components President Glenn Starkey talks about the importance of the customer and culture when developing technology solutions for the moldmaking industry.

8. MMT Chats: SPE MTD 2023 Mold Designer of the Year

MoldMaking Technology editorial director Christina Fuges sits down with the newly named SPE Mold Technologies Division 2023 Mold Designer of the Year to learn about his passion for mold design. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

7. MMT Chats: SPE MTD 2023 Mold Repair Person of the Year

MMT’s Christina Fuges sits down with the newly named SPE Mold Technologies Division 2023 Mold Repair Person of the Year to learn about his passion for mold repair. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

6. Stability, High Speed, Flexibility of Five-Axis Portal Milling Machine Reduces Rework for Mold Builder

The thermo-symmetrical construction of a five-axis portal milling machine with a center-guided Z-axis enables higher accuracy, reducing rework. Also, the symmetrical design and the guide arrangement increase stability and save weight, making the machine more dynamic, productive and energy-efficient.

Photo Credit: Zimmermann

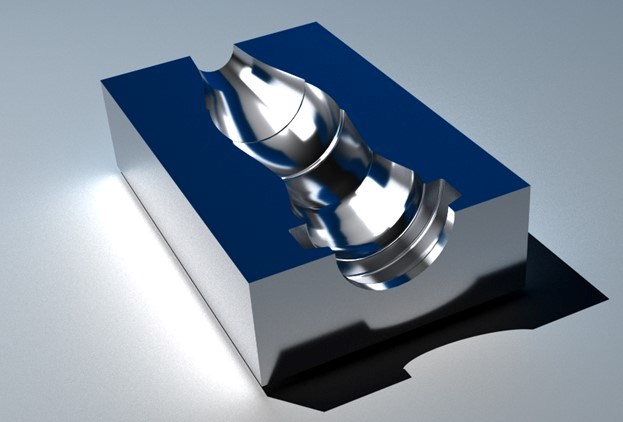

5. Improve Mold Machining With Equidistant Offset, Rest Finishing and Innovative Five-Axis Toolpath Strategies

The right CAD/CAM software helps mold builders better manage complex tool paths, improve the effectiveness of CNC finishing tool paths and take advantage of innovative five-axis machining toolpath strategies.

Photo Credit: Bob CAD-CAM

4. VIDEO: Hot Runners and Sustainability

Oerlikon HRSflow North America sales director Robert Harvey breaks down hot runner technology that addresses sustainability opportunities and challenges.

3. How to Overcome Cutting Tool Vibration

Advanced indexable milling cutting tool design provides secure, predictable machining, increased metal removal rates, reduced cycle times and fast changeovers.

Photo Credit: Sandvik Coromant

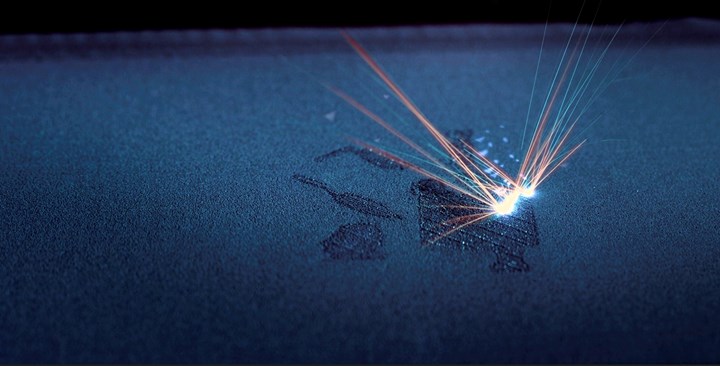

2. Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Photo Credit: EOS GmbH

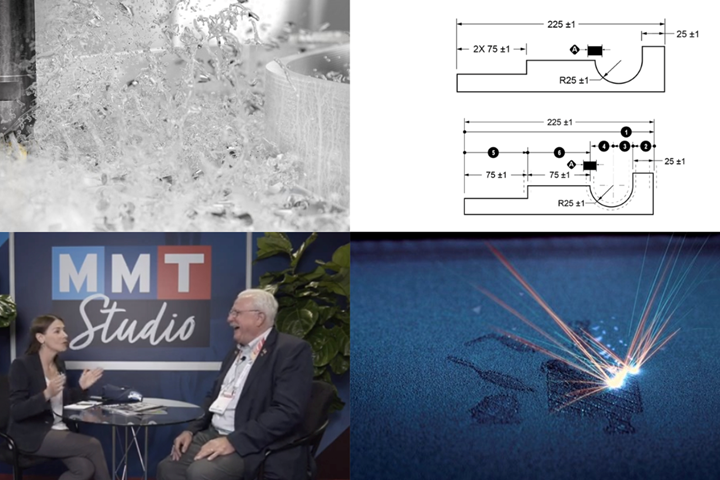

1. Tolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

RELATED CONTENT

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

-

How to Overcome Cutting Tool Vibration

Advanced indexable milling cutting tool design provides secure, predictable machining, increased metal removal rates, reduced cycle times and fast changeovers.

-

Tolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.